I. INTRODUCTION

Spin coating of resist and polyimide films onto silicon wafers is an important step in the fabrication of integrated circuits. These films may be used for planarization and photolithography (sacrificial layers), or as interlayer dielectric insulators (permanent layers). A complete review of the process may be found elsewhere,’ and we will include only a cursory review that emphasizes the points important for our discussion. The spin-coating process is carried out by dispensing a sufficient amount of liquid onto a wafer to flood it with the casting solution and then rapidly accelerating the wafer to the final spin speed. Rotation proceeds for a specified amount of time during which the film thins by a combination of fluid flow and evaporation. Finally, the disk is decelerated to rest. This procedure may then be followed by a baking step to remove residual solvent, or in the case of polyimide films, to cure the polymeric precursor to its desired final form.

II. EXPERIMENTAL PROCEDURES .

Typical conditions on which the spin-coating model is based. Spin-coating experiments were performed with two Du Pont polyimide precursor solutions, PI2525 and PI2545 Prior to spinning, the solutions were removed from a freezer and allowed to equilibrate thoroughly to room temperature. Dilutions were made using pure N-methyl-Z pyrrolidinone (NMP) solvent from Aldrich. Care was taken to minimize the exposure of the solvent and solutions to the atmosphere since NMP is extremely hygroscopic. The stock bottle of solvent was stored under nitrogen and small quantities were removed when required in a nitrogen glovebox.

Ill. SPIN-COAT MODELING

The spin-coating process can be divided into three stages: deposition and spin up, spin off, and film drying. Although these stages overlap slightly, their physics can be effectively modeled by separating them into three distinct stages and treating their mathematics individually. This approach differs from the “split model” in that mass fluid flow and solvent evaporation are not restricted from occurring simultaneously.

Fig1

A. Deposition and spin up

The liquid solution may be deposited in several different manners ranging from pouring the entire solution at the center of the disk and allowing it to spread radially over the film, to delivering the liquid in a steady stream moving radially over the rotating disk so that the deposited liquid forms a spiral. In all cases the amount of fluid deposited is such that the disk receives a large excess of fluid and is completely covered. Next, the disk is accelerated to its final rotational speed. It is here where the liquid undergoes a great deal of change from its initial state as a thick film essentially at rest to a thin film rotating with the disk.

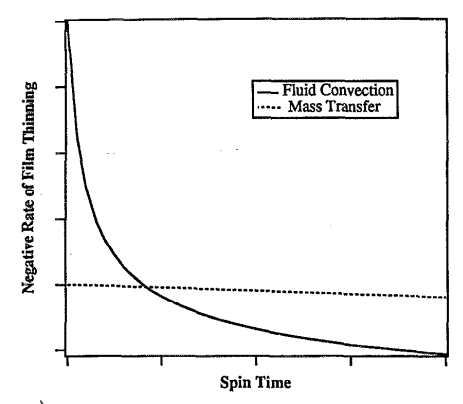

B. Spin off During this stage the film is thinned due to a combination of convection and solvent evaporation. The centrifugal forces act to drive the fluid radially off the edge of the disk impeded only by the viscous resistance. This radial flow quickly diminishes because the film has become exceedingly thin and evaporation of solvent has increased the viscosity by several orders of magnitude. During fluid flow the film is also thinned by solvent evaporation to the overlying atmosphere. It is the trade-off between these two mechanisms that controls the film thickness, uniformity, and the success of the spin-coating process.

C. Film drying

In this final stage of spin coating, fluid flow has essentially halted and further shrinkage of the film arises from solvent loss alone. Previously, the solvent. concentration profiles depended on fluid convection tlow through the cross terms in the solvent conservation equation. However, as the velocity components drop to zero, this dependence becomes unimportant, and solvent conservation may be considered independently. It is at this point where the spinoff stage ends and the film drying stage begins. We may continue to track the solvent concentration via the conservation equation or simply flash off any remaining solvent leaving a dry film behind. The former technique would be required when the film or underlying topography is not uniform because solvent diffusion may tend to modify existing free surface profiles.

上一篇: HF溶液中硅蚀刻过程中银的双重作用

下一篇: 等离子体中硅刻蚀的机理