Introduction

For the last 20 years, SiC has been investigated as a replacement for traditional etch stops in bulk micromachining due to its properties of being chemically inert in conventional etching solutions.1 It is also a desired material for high temperature devices due to its thermal properties. Applications for creating such devices as fuel atomizers, pressure sensors, and microfabricated molds can use typical wet etching techniques and take advantage of the properties of the SiC layer which make it chemically resistant.1 Particularly for SiCMEMS devices, large area substrates are essential. Due to the difficulty in manufacturing single growth crystal substrates, there has been much interest in epitaxial growth of single and poly-crystalline SiC layers on silicon. After the deposition, bulk etching is able to create microstructures and patterns suitable for the desired devices.

With bulk etching, one major concern is that the byproducts are released from the wafer into the bath. Depending on the open surface area of the patterned wafer, large amounts of silicates can be introduced. This can then create unwanted side effects such as decreased etch rate. By creating stable chemical conditions inside of the bath, it not only allows for consistent etch depth within and between lots, but it also allows for increased bath life which will lessen the cost of ownership for the process.

Experimental

Wet chemical processes were conducted on a fullyautomated GAMA™ wet processing station using 200mm wafers with a typical cavity structure. TMAH was used as an alkaline etchant at a concentration suitable for achieving a maximum etch rate. KOH was used as an alkaline etchant during subsequent testing on Solar wafers following the same methods outlined. Silicon etching processes were conducted with the aid of Naura-Akrion’s in-situ chemical concentration control system. Occasionally, samples of the baths were taken and titrated for comparison to the system’s readings. The goal for the TMAH testing was to fully etch through the wafers by maintaining a consistent etch rate throughout the entire process. For the KOH testing, a consistent etch rate and reflectance were measured to ensure the versatility of the system.

Results and Discussion

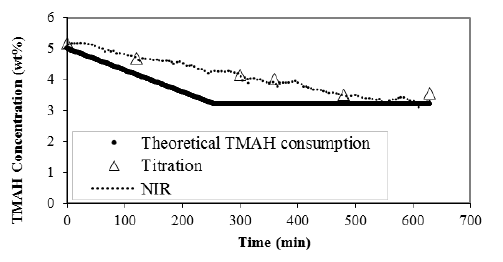

The chemical reaction for the anisotropic alkaline etching of silicon is well known and a variety of etchants can be used for the process (KOH, NaOH, TMAH). For the purpose of this study, the starting setpoint concentration of TMAH was 5% and allowed to drop to a minimum level of 3% whereafter the etch rate was kept constant. Through the course of the experiment, it was discovered that the generally held overall reaction mechanism for the etching of silicon with TMAH, as is shown in equation 1, did not match the real data.

Fig1

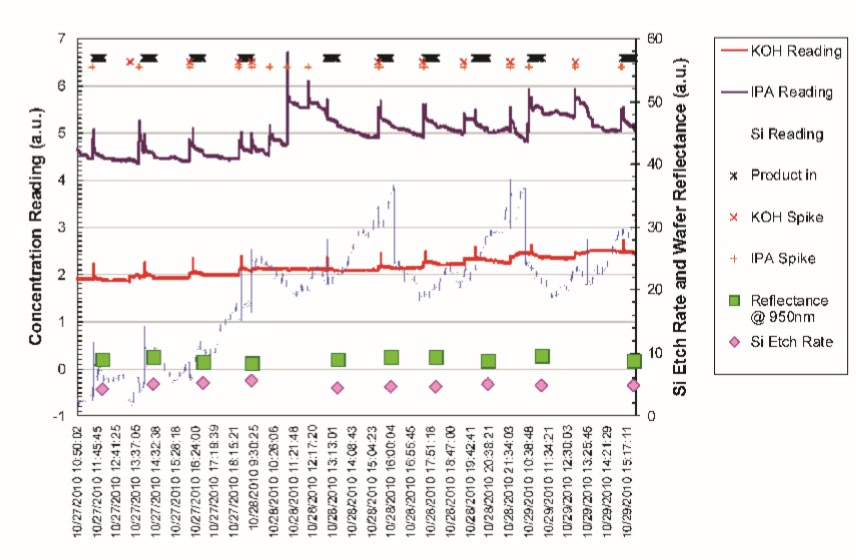

As can be seen in Figure 3, when the system initiates the concentration control process, the bath is then left at a steady state position. Therefore, it is important to set all parameters for upper and lower bounds to allowable values for maintained chemical concentration. In Figure 3, when the Si concentration reaches 5 g/L, the balanced volume of chemical being drained from the tank and added to the bath allows the concentration to stay at 5 g/L. The system does not correct itself to lessen the amount of Si in the bath significantly, as this would provide too much disturbance to the process. The TMAH concentration during the process is also maintained at a steady concentration, thus allowing the bath to sustain itself in an equilibrium between TMAH concentration and Si concentration for an extended period of time. The constant concentration of TMAH also allows the system to keep a constant etch rate, which was monitored before and after the system was activated. The production etch rate was the same across the experiment, and the qual etch rate was comparable to that of normal conditions. This dynamic equilibrium can maintain itself for weeks or even months depending on the process and the needs of the fab, as shown in the chart where the data is collected for 11 days with consistent results. A benefit of the SiC etch processes is that the material itself is inert to the normal chemical concentrations used for bulk etching, therefore the models necessary to track the silicate byproducts in the bath for typical bulk Si etching have already been created.

Fig3

Conclusions

Results have shown that Naura-Akrion’s novel closed loop concentration control system allows for a minimum usage of etchant, such as TMAH or KOH, while still maintaining the desired etch rate. This reduces the amount of chemical sent to the waste stream, decreasing the overall cost of ownership for the process. It also allows for consistent results within lots and between lots for wafer processing, effectively reducing the need to changeout baths after specific number of lots or time, depending on the demands of the process. This not only saves on more chemical cost, but also reduces the total time taken to qualify the baths in the long run after a chemical changeout occurs. The current state of SiC device manufacturing involves deposited films on bulk Si which must be etched. With closed loop concentration control, the process is more robust and results in less costly manufacturing.

上一篇: InGaAsP晶圆的化学蚀刻

下一篇: GaN的湿法化学蚀刻