1 INTRODUCTION

The photovoltaic technology is well established as a reliable and economical one for small sources of electricity and one of the most important factors is the optoelectronic conversion efficiency. In order to improve the optoelectronic conversion efficiency of monocrystalline silicon solar cells, the texturization was used to reduce surface reflectivity of silicon wafers and enhance light absorption. In the case of monocrystalline silicon, many studies were reported about the mixture of sodium hydroxide (NaOH) or potassium hydroxide (KOH) solution with isopropyl alcohol (IPA), because alkaline solutions etch the silicon anisotropically and generate small pyramids on the silicon surface.

2 EXPERIMENTS

Monocrystalline silicon wafers of P-type <100> orientation with a resistivity of 2 Ω-4 Ω. cm were used for this work. The size of the wafers was quasi-squared 15 mm × 15 mm which cut from the 125 mm × 125 mm. Before texturing, all wafers were handled by the following procedures. The first step was to degrease the samples by cleaning the wafers with the absolute ethanol in the ultrasonic cleaner for 10 minutes. In the next step, the samples were immersed in diluted hydrofluoric acid (HF, 4 wt%) for 1 minutes to remove the native oxide and rinsed in deionized water for several times. When all the cleaning work is over, the samples were heated by the drying oven to remove moisture of their surface.

The cleaned wafers were held vertically in a specially designed device, which is self-made. Then the wafers were etching in different concentration of sodium carbonate (Na2CO3) and sodium bicarbonate (NaHCO3).During the experiments, the reaction temperature and time should be well controlled. When the reaction is over, all the eroded wafers were washed again into the absolute ethanol solution and deionized water for 10 minutes. After that, they were dried in the drying oven for tests. In the en, we obtained the silicon wafers surface reflectance data using UV-Visible spectrophotometer. In addition, images of surface morphology was measured by a scanning electron microscopy (SEM).

3 RESULTS AND DISCUSSION

3.1 The effect of different concentration of sodium carbonate on the texture.

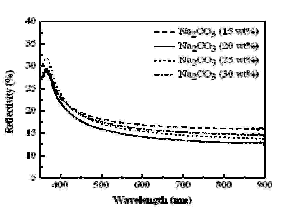

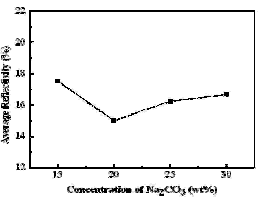

Primarily, the effect of the Na2CO3 concentration on the surface reflectivity was investigated. The solution temperature is 85°C and the etching time was carried out at 30 min. The reflectivity was measured for samples textured using 15 wt%, 20 wt%, 25 wt% and 30 wt% Na2CO3 individually. As shown in Fig. 1, the reflectivity was found to decrease with increasing Na2CO3 concentration up to 20 wt%, when the concentration of Na2CO3 is over 20 wt%, the reflectivity start to rise. Fig. 2 shows the weighted average reflectivity in the range of 400 nm-800 nm spectrum range, we can see the lowest value is 14.98%. Fig. 3 is the SEM images of monocrystalline silicon wafers texture, which has shown the pyramids structure. All these experiments results mean that it is better to use 20 wt% Na2CO3 when we use the single reagent.

3.2 The effect of different concentration of sodium bicarbonate on the texture.

Besides the existing 20 wt% concentration of Na2CO3, now we add some different concentration of NaHCO3 (2 wt%, 4 wt%, 6 wt% and 8 wt%). Samely, we fix the solution temperature is 85℃ and the etching time is 30 min. From the reflectivity curves of Fig. 4, we can see a minimum reflectivity when the NaHCO3 concentration was increased to 4 wt%. Fig. 5 shows the lowest weighted average reflectivity is 12.84%. Fig. 6 is the SEM photograph. It seems that this kind of combined reagent system can successfully texture monocrystalline silicon for solar cells.

Fig1

4 CONCLUSIONS

In this work, a texturization technique for crystalline silicon solar cells using sodium carbonate and sodium bicarbonate

solutions has been investigated. We can found that it is possible to optimize the reflectivity values of the samples by varying the Na2CO3 and NaHCO3 concentration of the solution, the solution temperature and the etching time, thus obtaining low reflectivity values comparable to the ones obtained in IPA-based solutions.

It is shown that our optimized process lasted for 30 min at 85°C using a solution containing 20 wt% Na2CO3 and 4 wt% NaHCO3. After texturing, for monocrystalline silicon wafers, we can obtain reliable and uniform pyramidal texturing surfaces with an average weighted reflectivity of 12.84%. Our approach is giving high hopes for the industrial production of high efficient solar cells.

下一篇: 晶片键合过程中保持晶片对准精度的方法