1. Introduction

Semiconductor wafer bonding has been a subject of interest for many years. Wafer bonding with intermediate organic or inorganic adhesive materials has many advantages over conventional wafer bonding techniques such as the relatively low bonding temperatures, the absence of electric voltage or current, the compatibility with standard CMOS wafers and the ability to join practically any kind of wafer materials. Adhesive wafer bonding requires no exceptional wafer surface treatment or planarisation steps. Structures and particles at the wafer surfaces can be tolerated and compensated for some extent by the adhesive material. It is also possible to locally bond lithographically predefifined wafer areas with selective adhesive wafer bonding [1,2]. Adhesive wafer bonding can be applied to fabrication [2], integration [3–9] and packaging [9–11] of advanced microelectronic and microelectromechanical systems (MEMS). Another large ap-plication area of adhesive wafer bonding is the fabrication of microflfluidic devices [13].

Accurate alignment of the bonded wafers is essential for many of the above mentioned applications. The suppliers of commercial bonding equipment have implemented different techniques to align the wafers during bonding [10–12]. The initial attainable wafer alignment accuracy with these techniques is typically 2–5 m before the bonding takes place. However, during adhesive wafer bonding, the wafers move relative to each other when the intermediate adhesive material transforms into a liquid state to wet the wafer surfaces and to achieve bonding. Shear forces that are introduced from the bond tool to the wafer stack cause the wafers to shift, since the liquid adhesive is not capable of bearing the shear forces. The appearance of the shear forces is practically unavoidable when the two wafers are pushed together with the bond tool. Consequently, none of today’s commercially available wafer bonding equipment repeatedly obtains wafer alignment accuracies better than 10–15 m in adhesive wafer bonding although the pre-bond wafer alignment is typically 2–5 m [14].

2. Adhesive wafer bonding and wafer alignment

Wafer bonding techniques are based on the fact that atoms and molecules adhere to each other when they are brought in suffificiently close contact. The cohesion of atoms and molecules within a solid material as well as in between two solid materials is ensured by a number of basic bond types, which are covalent bonds, van der Waals bonds, metallic bonds and ionic bonds [15]. To bring two material surfaces in suffificiently close contact to achieve bonding, at least one material surface must deform to fifit the other. When an intermediate adhesive material is used to join two solid-state surfaces, the adhesive material deforms and wets the surfaces to be bonded. Therefore, the adhesive material exists in a liquid or viscoelastic state at a certain point of the bonding process, to deform and fifit to the surface profifile of the wafers to be bonded. The adhesive then hardens into a material that is capable of bearing the forces needed to hold the wafers together.

3. Experiments and results

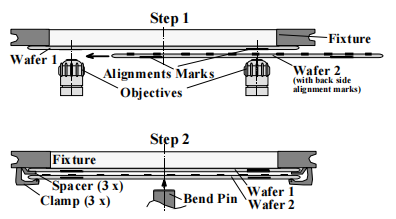

In the present study of alignment in adhesive wafer bonding we have used negative photoresist ULTRA-i 310 from Shipley and benzocyclobutene (BCB) from Dow Chemical as adhesive materials. Both materials are thermosetting polymers that cross-link when heated. During the cross-linking they flflow for a short time to achieve bonding. In all experiments we have used 2 m thick coatings that are spun on one of the 100 mm diameter wafers. The coatings (both BCB and ULTRA-i 310) were pre-cured for 2 min on a hot plate at 70 ◦C to remove the solvents. Then the wafers were aligned with a BA6 bond aligner from Karl Suss and transferred to a SB6 substrate bonder from Karl Suss that is equipped with a universal bond tool. The thickness of the three spacers of the fifixture was 50 m. The curing temperature during the bonding process was 110 ◦C for 20 min with a temperature ramping time of 15 min from 50 to 110 ◦C when ULTRA-i 310 was used as the adhesive material and 200 ◦C for 2 h with a temperature ramping time of 40 min from 50 to 200 ◦C when BCB was used as the adhesive material. The curing temperatures are determined by the curing requirements of the respective polymer material. To obtain void-free and high quality wafer bonds with thermosetting adhesives, the wafers must be pressed together using the bond chucks during the time the adhesive is cured [1,3]. The bonding pressure was 2 bar in all experiments. A detailed discussion of the inflfluence of the bonding parameters on the resulting bond quality has been presented elsewhere [1,3,8,13].

Fig1

To determine the achievable wafer alignment accuracy during adhesive bonding a number of different bonding experiments have been conducted. Table 1 shows a list with the performed experiments, the wafer surfaces on which the adhesive coatings were applied and the corresponding alignment results. The 300 m thick silicon wafer from wafer Combination III in Table 1 contains a patterned surface. This pattern consists of approximately 2.3 million aluminium squares that are 2.1 m high and 5 m × 5 m in size. The squares are grouped in 15 arrays with 480 × 320 squares and a pitch size of 40 m × 40 m.

The initial wafer alignment accuracy before the adhesive bonding process (pre-bond alignment accuracy) was equal or better than 5 m in all experiments. After the bonding (post-bond alignment accuracy), the wafer alignment accuracy was only 15–50 m. The decrease in alignment accuracy occurred with ULTRA-i 310 and with BCB as the intermediate bonding material. The loss of alignment cannot be attributed to the difference in thermal expansion between the silicon and the Pyrex glass wafer since misalignment in the same order of magnitude also occurred when silicon wafers were bonded to silicon wafers. Pyrex glass wafers have a thermal expansion coeffificient of approximately 3.25 ppm and silicon of 2.7 ppm. The expected misalignment due to the difference in thermal expansion between Pyrex glass and silicon is 1.4 m for a temperature difference of 70 ◦C and a distance of 70 mm between two alignment marks.

上一篇: 碳酸氢钠溶液氧化单晶硅太阳能电池的研究

下一篇: 不同电解质对多孔氮化镓的影响