Introduction

Plasma-deposited carbon thin films have been receiving increasing attention due to their excellent mechanical, chemical, electrical, optical and acoustic properties. Their properties can be fine-tuned for specific applications by choosing the appropriate deposition conditions. Thus, carbon films can be deposited in the form of graphite, diamond, diamond-like carbon, (DLC), diamond-like hydrocarbon and amorphous carbon. Diamond and graphite are the crystalline allotropes of carbon. The isotropic, tetrahedrally-coordinated structure of diamond and the layered, two-dimensional structure of graphite represent the two structural extremes of carbon. Amorphous carbon is yet another allotrope of carbon, whose structure is isotropic. The bonding microstructure of amorphous carbon has been of intense interest and speculated for more than a decade. The details of the microstructure are still open questions.

The earliest carbon films were deposited from carbon ions extracted from a carbon arc in argon (Aisenberg and Chabot, 1971). Spencer et al. (1976), Holland and Ojha (1976, 1978, 1979), Ojha and Holland (1977), Weissmantel (1979, 1982), Wada et al. (1980), Bubenzer et al. (1983), Vora and Moravec (1981), and Angus et al. (1968, 1984) were among the most active early workers. Their work led to an almost explosive growth of the field, which has been reviewed thoroughly in the last few years (Angus et al., 1986, 1988, 1989; Phillips, 1979; Martin et al., 1989; Tsai and Bogy, 1987; Messier et al., 1987; Bachmann and Messier, 1989).

Experimental Methods

A commercial parallel-plate plasma reactor ( PlasmaTherm model 730/730) described earlier (David et al., 1990) was used for the deposition and etching experiments. The deposition chamber consists of a powered upper electrode and a grounded lower electrode. The chamber walls were also grounded. Single crystal silicon [IOO] and pyrex glass substrates were used as substrates for deposition and were stuck to the u2per electrode by silver paint. The temperature of the upper electrode (0.28 m dia.) was maintained as 25°C by circulating ethylene glycol/ water coolant mixture, while the temperature of the lower electrode was maintained at 400°C by a resistance heater. In the more conventional electrode configuration, substrates are placed on the lower, powered electrode and heated to the desired temperature (25-400°C). The reactor volume is 0.006 m3, and the active discharge volume is 0.0025 m3. Four outlet ports (0.04 m'), arranged 90" apart on a 0.33-m-dia. circle on the lower wall of the reactor, lead the gases to a Roots blower backed by a mechanical pump. A capacitance manometer monitored the chamber pressure that was controlled by an exhaust valve and controller. The base pressure in the reactor was 0.13 Pa (1 mtorr), and the combined desorption and leak rate into the chamber was about 1.7~ lo-'' m3/s (0.01 std. cm3). A 600-W generator delivers RF power at 13.56 MHz through an automatic matching network to the reactor.

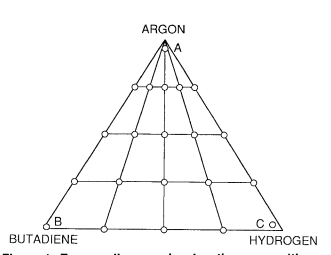

Fig1

ResuIts

Growth environment

The pressure, the substrate bias voltage, and the nature and concentration of species present in the discharge are the important variables that determine the ion energy distribution and the film properties (Angus et al., 1986). At a fixed pressure, the average ion energy will increase with the bias voltage Vb, which depends on the feed gas composition and the power level. The ion energy distribution can change in different ways which depend on how the bias voltage is varied.

Film hardness and cracking

Films deposited in a hydrogen-rich atmosphere were soft and easily scratched, while films deposited at large C/H ratios were hard. In an argon-free gas mixture, even though the bias voltage varies only from 270 V to 330 V when the C/H ratio is changed from 0.67 to 0.0, large differences in h, ‘tr d ness were observed. The hardest films were deposited in the argon-rich corner of the ternary diagram, when the UH ratio is large. These films were difficult to scratch even with a silicon carbide scribing tool. However, as can be seen from Figure 4, it is very interesting to observe that precisely these films had the lowest deposition rates. There appears to be a trade-off between the rate of deposition and film hardness.

Conclusions

Diamond-like carbon films were deposited from ternary mixtures of butadiene, argon and hydrogen. Plasma stability was improved by adding argon. The IR spectra of the films deposited under three different composition extremes reveal sp3 C-H bonds to be more prevalent than sp2 C-H bonds. Films adhered better to silicon than to glass, and the failure mechanisms were substrate-specific. The hardness of the films ranged from easily scratchable to difficult-to-scratch with a silicon carbide scribing tool. The hardest films were deposited under an abundance of argon, and the softest films were deposited under an abundance of hydrogen.

上一篇: 硅的湿化学蚀刻机理

下一篇: 太阳能电池减薄中酸性溴溶液的化学处理