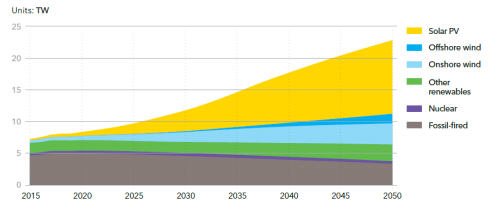

The solar photovoltaic (PV) market is growing rapidly, with the cumulative global PV capacity growing from 100.5 GW in 2012 to 480 GW in 2018 [1], [2]. According to predictions by DNV GL [3], presented in Figure 1-1, the world installed power station PV capacity will reach 11.6 TW by 2050, showing a big growth. Moreover, at that time, the predicted power station PV capacity will be almost equal to the capacity of all the other power sources combined.

Two layers of polymer material (e.g. Ethylene Vinyl Acetate or EVA, ionomer, etc.) [17] are used as an encapsulant, one on the top and one on the back side of the cells. For the final encapsulation, a piece of glass is placed on the top of the module for the protection of the PV cells from the various environmental factors and mechanical support. A sheet of polymer (e.g. Polyethylene Terephthalate (PET), Tedlar Polyvinyl Fluoride, etc.) [18], mono- or multi- layer, or another piece of glass is placed on the back of the module to form the backsheet, for the same reasons. Finally, an aluminium frame is usually built around the edges of a PV module for mechanical support and further protection of the PV module from moisture penetration [19]. To complete the module, a junction box (that can be seen in Figure 1-4b) is attached to the rear side of the module, that contains the bypass diodes and the cables which connect the cell strings (sequences of PV cells) to the external terminals. Bypass diodes are used to protect the modules from local overheating when some of the cells become disconnected or shaded.

The research reported in this thesis formed a part of the Solar-Train project under grant agreement No 721452, funded by European commission under the Marie Skłodowska-Curie Actions. The overall aim of that project was the forecasting of the PV module lifetime by the study of the different degradation mechanisms, the understanding of the effect of climate on them and the prediction of the performance reduction due to them. The Solar-Train partners and the work package collaborations are presented in Figure 1-5 and Figure 1-6, respectively.

Fig1

Two layers of polymer material (e.g. Ethylene Vinyl Acetate or EVA, ionomer, etc.) [17] are used as an encapsulant, one on the top and one on the back side of the cells. For the final encapsulation, a piece of glass is placed on the top of the module for the protection of the PV cells from the various environmental factors and mechanical support. A sheet of polymer (e.g. Polyethylene Terephthalate (PET), Tedlar Polyvinyl Fluoride, etc.) [18], mono- or multi- layer, or another piece of glass is placed on the back of the module to form the backsheet, for the same reasons. Finally, an aluminium frame is usually built around the edges of a PV module for mechanical support and further protection of the PV module from moisture penetration [19]. To complete the module, a junction box (that can be seen in Figure 1-4b) is attached to the rear side of the module, that contains the bypass diodes and the cables which connect the cell strings (sequences of PV cells) to the external terminals. Bypass diodes are used to protect the modules from local overheating when some of the cells become disconnected or shaded.

下一篇: 用于MEMS应用的玻璃湿法蚀刻