1. Introduction

Beside silicon glass is the second widely used material in fabrication of MEMS devices, mainly due to its interesting properties such as: high chemical resistance, high heat resistance, high electrical isolation, biocompatibility, large optical transition range and low optical absorption.

The present paper is focused on characterization of wet etching process for glasses, with main targets on one of the most used Pyrex glasses (Corning 7740). In the next sections, after the description of the general methods for glass machining, the inflfluence of glass composition, methods to improve the etching rate, the explanation of defect generation, the inflfluence of residual stress in the masking layer, the inflfluence of the hydrophilicity of the mask surface as well as the characterization of the main masking layers and the quality of generated surface will be analyzed. The paper reports also the best results achieved in deep wet etching of glass: 1 mm-deep wet etching using a low stress amorphous silicon/ low stress silicon carbide/photoresist mask. A solution to generate smooth surface using wet etching process in HF/HCl solution is also presented.

2. Glass etching techniques

Dry etching techniques include plasma and laser etching of glass. Ronggui and Righini in [14] reported the fifirst etching of glass in plasma with an optimal etching rate of 10 nm/min. Better results are reported using Deep RIE in ICP systems in [15] – using SF6as gas and a 20 µm-thick Ni mask – and in [16] – using C4F8 chemistry and 40 µm-thick bulk silicon as masking layer. The main advantage of this technique is the opportunity to generate structures with high aspect ratio, or microchannels with vertical walls. The disadvantages of plasma etching consist of relatively low etching rate (0.5–0.6 µm/min) which is halve by the cleaning process of the equipment required usually after each 10 µm depth etch. The surface generated (high energy sputter etching process) is another disadvantage of the process.

3. Inflfluence of glass composition

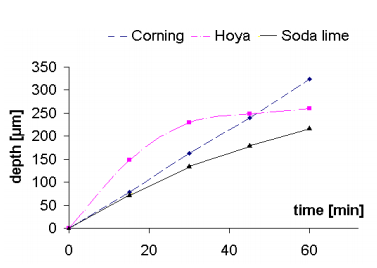

The wet etching of glasses is mainly performed in HF-based solutions, but etching of glass in KOH solution had been reported [27]. Due to difffferent composition the etching rate is difffferent. An example is presented in Figure 1 where three difffferent glasses (Corning 7740, Soda lime and Hoya SD-2) were wet etched in HF 49% solution. As can be observed, only Corning 7740 presents a constant etch rate, while for the other two glasses there is a parabolic variation of depth in time.

4. Etch rates

An important factor in deep wet etching of glass is the etch rate. In some cases of wet process the selectivity of the etching (defifined as the ratio of the etch rate of masking layer to the etch rate of materials to be processed) is preferred as the parameter. In wet etching of glass, materials used as masking layers (silicon and gold) are inert in the HF-based etchant, the etching process being limited by the defects of the masking layer and the penetration of the etchant through these defects. For this reason a fast etch rate of glass will lead to a deeper etching while the defect generation will be maintained at the same rate each time.

上一篇: 晶体硅光伏组件的腐蚀及其对性能的影响

下一篇: 异丙醇酒精蒸发法对硅的动态湿蚀刻