A very promising process flow for industrial-type PERC solar cells includes double sided texturing, double sided POCl3 diffusion and single sided wet chemical polishing [1]. Energy conversion efficiencies of 20.2% for PERC solar cells based on this process flow were recently reported [2]. However, these results were achieved using a laboratory type RCA clean after polishing and prior to ALD-Al2O3 deposition, which is costly in industrial process flows.

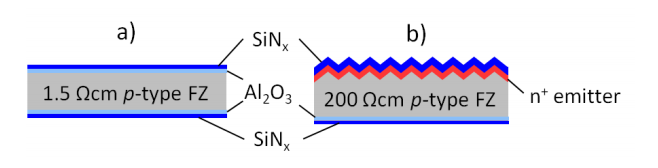

We evaluate four different cleaning sequences targeted for industrial application prior to AlOx/SiNy passivation: 1) pSC1, HF/HCl; 2) pSC1, HF/HCl, HF/O3; 3) HF/O3; 4) PSG-etch (1% HF) and compare the results to a laboratory type RCA clean. The cleaning sequences 1 and 2 are designed as shortened versions of the RCA clean. The pseudo-SC1 (pSC1) clean applies KOH/H2O2 chemistry and aims at removing organic contamination similar to the SC1 in the RCA clean. The HF/HCl clean removes metallic contaminants similar as the SC2 clean in the RCA clean sequence. Both, the pSC1 and HF/HCl clean, are well known as typical industrial cleans prior and post texturing, respectively. In cleaning sequence 3, SiO2 formed by ozone is removed by HF chemistry. The resulting etching of the silicon wafer surface might remove contaminants from the surface. The PSG-etch (clean 4) is chosen because it is the typical clean of a standard full-area Al-BSF production process applied after phosphorus diffusion and before Al screen-printing. To evaluate the impact of a cleaning sequence on the subsequent rear side passivation only, we fabricate test wafers for measurement of the effective lifetime τeff as shown in Fig. 1a). Using 1.5 Ωcm float zone (FZ) material these wafers are cleaned with the 5 cleaning sequences as described above. Then the ALDAl2O3/PECVD-SiNx passivation layer stack is deposited on both sides. After a firing step τeff is measured using a Sinton lifetime tester.

Figure 2 shows, that highest lifetimes of 1-2 ms are achieved using the RCA clean or one of the HF/O3 based cleaning sequences. Using Spass=W/2* τeff this corresponds to a surface recombination velocity (SRV) of 8-15 cm/s. The two wafers cleaned with pSC1 + HF/HCl show lower lifetimes of 700 μs and 1200 μs yielding Spass values of 12-20 cm/s. The lowest lifetime of around 500 μs – corresponding to an Spass of 30 cm/s – is obtained for the PSG etch, probably due to insufficient removal of metallic contaminants .

Fig1

Measurements of the internal quantum efficiency (IQE) in the infrared regime as displayed in Fig. 5 show comparable values for most cleaning sequences except for the PSG-etch, which exhibits significantly lower values. Using our in-house developed silicon solar cell analysis software SCAN which is based on the analytical model for the QE introduced in [7], we model the experimental reflectance and IQE data to obtain the effective SRVs at the rear Srear. For the PSG-etch we extract 330 cm/s, whereas the other cleaning sequences show values <50 cm/s indicating that the lower Voc and Jsc values of the cells cleaned with the PSG-etch primarily result from higher recombination at the rear.

When moving from 3 μm to 12 μm polishing removal, the emitter saturation current densities decrease from 110-140 fA/cm² down to 70-95 fA/cm² for both cleaning sequences as shown in Fig. 6a). The improved J0e values are very likely due to a reduced phosphorus concentration on the front surface caused by the longer gas phase etch during polishing [9]. The low J0e values demonstrate, that both cleaning sequences sufficiently remove the porous silicon to allow a good emitter surface passivation while maintaining emitter sheet resistances below 70 Ω/sq as shown in Figure 6b), where both cleaning sequences only contribute about 2 Ω/sq sheet resistance increase as measured on reference wafers. The QSSPC measurements show effective lifetimes τeff around 1 ms for all polishing removals, where wafers cleaned with pSC1, HF/HCl, HF/O3 obtain 100-150 μs higher lifetimes compared to the pSC1, HF/HCl, HF-Dip clean. Accordingly, both cleaning sequences allow an excellent rear surface passivation quality with SRVs Spass < 15 cm/s when combined with an Al2O3/SiNx rear passivation.

下一篇: MgO的湿法清洁