The feasibility of a desired shape of a microstructure on any kind of silicon wafer (e.g. (111), (110), or (100)) is determined by studying the etched profile of various shapes of masking patterns on the respective wafers. This paper deals with microstructures on Si(100) wafers. In order to design the compensating pattern for the realization of convex corners, the identification of the undercutting planes, their etch rates and their angles are required.

Round shape masks were designed for the fabrication of rounded concave corners, whereas several kinds of compensating geometries at the convex corners were tested, including a <100> oriented beam, square and triangular shapes, as illustrated in figure 1. These are used for the realization of grooves for chip isolation, and mesa structures that are framed around by V-grooves. For the production of 45º mirrors with highly smooth surfaces for optical MEMS applications, rectangular mask openings aligned along the <100> direction were used.

We evaluated the etching characteristics, such as (1) the etch rate, (2) the etched surface morphology, and (3) the amount of undercutting at the sharp convex and rounded concave corners, in both pure and TMAH + NC- 200. The etch depth was measured using a surface profiler (DEKTAK 3 ST). The dimensions of the etched profile were measured using an optical microscope (OLYMPUS STM6) fitted with an angular and linear dimensions measurement system. The surface roughness was measured with a non-contact 3D optical profiler (ZYGO).

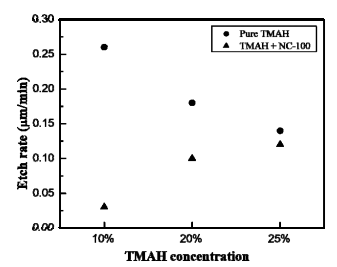

The eth rates measured in pure and NC-200 added TMAH are shown in Fig. 2. When NC-200 is added in TMAH, the etch rate is reduced to a considerably low level at low concentration (10 wt%), while at high concentration (25 wt%) it is not affected significantly. In pure TMAH, the average etched surface roughness of {100} increases with decreasing concentration of the etchant. The etched surface morphology is very smooth at high concentration, whereas it is full of hillocks at low concentration, as shown in Fig. 3. The incorporation of NC-200 improves the surface morphology dramatically at low concentration by preventing the formation of hillocks. At high concentration, it does not affect notably.

Fig2

If one is required to fabricate square shaped cavities with smooth surfaces and/or to release the microstructures made of dielectrics (e.g. SiO2, Si3N4) or metals (e.g. Cr, Au) by wet anisotropic etching using TMAH, a high concentration of 20 or 25 wt % is recommended as it provides negligible undercutting at concave corners and severe at convex corners. On the other hand, in order to achieve minimum undercutting by preserving the smooth surfaces and a reasonable etch rate for the fabrication of microstructures with rounded and sharp convex corners, 25 wt% TMAH + NC-200 is the most favorable choice.

上一篇: 硅薄膜太阳能电池的铝薄膜

下一篇: HF溶液中硅基质的铜污染机理