This paper concerns with the basic investigations on the wet chemical etching of semiconductors. First, a method to observe the etched cross-section of aluminum layer is developed. It is applied to the observation for the cross-section of a test piece etched in a quiescent etchant. The observation successfully makes clear the time variation for the geometry of the etched cross-section, and elucidates the effffects of the resist width on the geometry. Secondly, the numerical simulation for the etching process is performed. The simulated geometry of the etched cross-section is confifirmed to agree with the observed result, indicating that the present numerical simulation is effffectively used to predict the geometry of the etched cross-section.

In the wet chemical etching, the etchant is generally sprayed onto the rotating wafer, and the Al layer is etched due to the chemical reaction with the etchant. Since the geometry of the Al layer changes in accordance with the etching, the flflow and diffffusion of the etchant are extremely complicated. It is, therefore, very diffiffifficult to determine the best fabrication conditions, such as the etchant issuing velocity, the wafer rotating speed and the etchant time, which yield the desirable etched geometry.

The test piece is took out from the etchant after every 1 minute to observe the etching process. The etched test piece is coated with a thin resin fifilm, and then the crosssection is shaped by a FIB (Focused Ion Beam). The fifilm coating is indispensable to protect the resists from the FIB processing, making it possible to observe the effffect of the resist on the etched cross-section. A STM (Scanning Ion Microscope) with spatial resolution of 7 nm is employed for the observation.

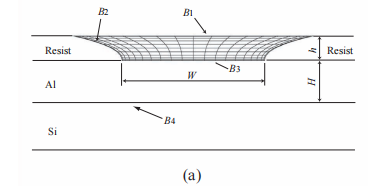

Fig1

The geometry of the cross-section for the Al layer of W=W1 changes as the function of etching time as shown in Fig. 4, where the x and y coordinates are nondimensionalized by the resist width W and the Al layer thickness H, respectively. Though the etching proceeds in the x and y-directions, the etching amount in the ydirection is markedly larger. The bottom of the Al layer is always flflat, and the width almost coincides with W.

The simulated geometries of the cross-section for the Al layer of W=W1 are shown in Fig. 7, where the results for the etching time of 1, 3 and 5 minutes are indicated. The etchant concentration is also presented. It is found that the Al layer is etched with the lapse of time and that the etching also proceeds in the lateral direction just under the resist edges. Though the concentration distributes almost uniformly at t=1 min, it decreases near the Al surface with the lapse of time.

上一篇: HF溶液中硅基质的铜污染机理