An effective wet cleaning process, optimized for low temperature Ge epitaxy on thin Ge or SiGe structures with reduced surface roughening, is proposed. It is found that the HF+HCl cleaning is the most effective wet cleaning method that is applicable to the low temperature thermal cleaning. It is also found that temperature of the thermal cleaning appropriate for thin Germanium on Insulator (GOI) substrates is approximately 450 o C. Moreover, the successful formation of the strained-GOI structures is demonstrated by applying these wet and thermal cleaning processes to thin Silicon-Germanium on Insulator (SGOI) substrates.

In this report, an effective wet cleaning process optimized for GOI and Ge-rich SGOI surfaces, which can be combined with the low temperature thermal cleaning, is proposed. Moreover, the epitaxial growth of (strained-) Ge layers on (S)GOI substrates by using this cleaning procedure is demonstrated.

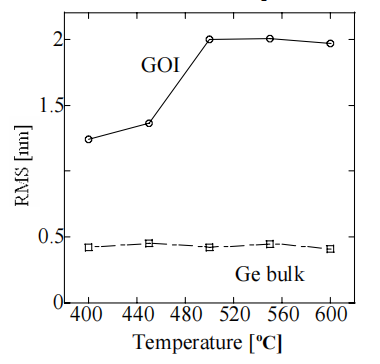

First, the upper limit of the temperature of the thermal cleaning is evaluated. The variations of the RMS values (@ 10µm*10µm) of GOI and Ge bulk substrates measured by AFM are plotted in Fig.1 as a function of the H2 -baking temperature.

Fig1

No surface roughening is observed on Ge bulk surfaces even if the cleaning temperature is raised up to 600 o C. The surfaces of GOI layers, however, become rougher at temperatures higher than 450 o C. It has been confirmed that the upper limit of the thermal cleaning for GOI substrates is lower than that for Ge bulk substrates. Thus, more effective removal of remaining surface oxides and impurities is strongly needed in the wet cleaning processes.

Here, both surface conditions of the HF-cleaned Ge surfaces and the HF+HCl-cleaned substrates have been characterized by TDS as shown in Fig.4 and Fig.5, respectively. No distinct difference in the hydrogen desorption spectra is observed between HF-cleaning and HF+HCl-cleaning. On the other hand, the Cl and HCl desorption peaks are observed only in HF+HCl-cleaning spectra. These results suggest that Ge surfaces are partially Clterminated and Ge-H bonds are not stable, as previously reported .

Here, the substrates cleaned by the different solutions were loaded into the deposition chamber together and Ge layers were grown on them at the same time. Many pits, which are considered to be formed by remaining surface oxides on the GOI substrates, are observed on the surfaces of the Ge layers on the HF-cleaned GOI substrates, while the Ge layers having flat surfaces are grown on the HF+HCl-cleaned GOI substrates. Thus, it is found that the HF+HCl cleaning is the most suitable wet cleaning method which can be combined with the low temperature thermal cleaning.

上一篇: 半导体湿法化学刻蚀工艺观察