The deleterious effects of metallic contamination on silicon devices have drawn the attention of researchers since the early days of the semiconductor industry. 15 Among all the metallic contaminants, iron and copper are recognized to be the most problematic ones. Not only can they easily be transferred to the wafers from nonoptimized process tools" and low quality gases and chemicals,1' but they also strongly reduce the yield of silicon devices.'2 Metals can degrade the dielectric properties of gate oxides causing premature breakdown13"4 and diffuse into the bulk of the silicon material resulting in an increase of the junction leakage' and a reduction of the minority carrier lifetime.

Initially, a comprehensive study of the characterization techniques was performed for the case of Fe contamination in p-type silicon. For that purpose, CZ, p-type, <100>, 6 to 10 and 24 to 36 Cl cm, 125 mm diam wafers, with medium oxygen content, received uniform Fe contamination from Fe spiked (0.25:1:5) NH4OH:H,O,:H,O (SC1) solutions." The resulting Fe surface concentration measured by vapor phase deposition (VPD)-DSE-TXRF" was in the range between 10' and iO" atom/cm'. The surface contamination was subsequently driven into the wafers by thermal treatments at 900°C for 30 mm in dry 0,, wet H, + 0, (pyrophoric), or N, ambients. The ramp-up for the treatments in oxidizing ambient was done in 5% 0,. The cool-down in all cases was performed at a rate of 5°C/mm to 650°C in N,. The samples were then removed from furnace to room temperature in 10 mm. This procedure was intended to reproduce typical processing conditions found in semiconductor manufacturing.

A second set of experiments was performed where both n- and p-type substrates (Table I) were used to address the impact of the doping type on the activity of the impurities in silicon. The Fe contamination was deposited as described before from spiked SC1 solutions in a controlled and uniform way. Copper was transferred to hydrophobic wafers from Cu spiked diluted HC1 (1:l0) solutions. The resulting surface contamination was in the range of 10' to 5 X 10" atom/cm'. ' In this second set of experiments, annealing in dry oxygen at 900°C for 30 mm was used to drive the impurities into the wafers.

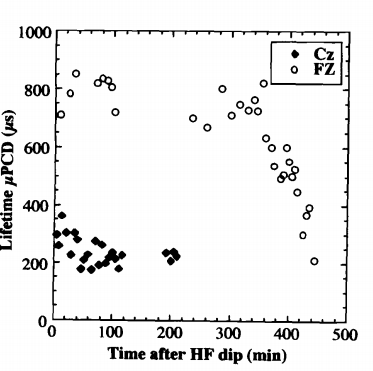

Fig1

Comparison of the impact of Fe and Cu contamination in p- and n-type silicon.—Surface Fe contamination was intentionally deposited in a controlled way on n- and ptype wafers (Table I) from spiked SC1 solutions and was driven into the substrates by annealing at 900°C for 30 mm in dry 02. The bulk [Fe] was measured on the p-type samples with SPV and the same levels of Fe contamination were assumed to be present in the n-type wafers that have been processed by the same conditions, following the approach used by Ref. 7 and 8. The Fe is expected to be paired with B in the p-type wafers and to be in interstitial sites in the n-type material. The measured T,CD plotted as a function of the bulk [Fe] (Fig. 8) shows that Fe is more detrimental to p-type material than to n-type.29'3° Apparently, the T,CD on the contaminated FZ wafers of both types is slightly lower than on CZ ones.

下一篇: HF溶液阳极氧化形成多孔硅层的机理