The billion dollar silicon industry is built on the extreme uniformity, chemical, and mechanical strength of perfect crystals of silicon configured in the shape of a wafer for standard integrated circuit processing. Silicon is an ideal substrate for creating transistors. Thinning the silicon integrated circuit (IC) substrate has now become a common process approach to maintain the trend established by Moore’s law and to meet the packaging form factor required by consumer applications. The thinned silicon wafer can be used in a stand alone thin form factor package, or combined with other thinned silicon device wafers to create a three dimensional stack IC structure (3D-IC). A thinned silicon IC wafer is very difficult to handle. Therefore it generally requires the use of a carrier substrate attached with a temporary bonding method as an aid to handling.

While it is convenient to use a known silicon wafer as a mechanical carrier wafer during process development activities for wafer thinning, it is illustrative to consider other alternatives, such as glass wafers. Glass wafers have attributes such as optical transparency that enable visible inspection and other light-based processing techniques, and innovative forming processes that minimize or eliminate fabrication steps, for example. To be considered as a drop in alternative carrier, a glass wafer needs to have similar mechanical properties as a silicon wafer. This includes form and fit to travel in and out of standard fabrication tools plus the basic materials properties required to act as a carrier.

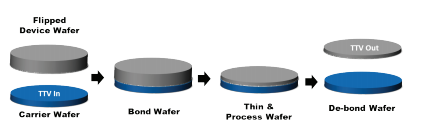

Figure 1 shows a simplified process for creating a thin silicon device wafer. Depending on the application, the final device wafer thickness may be anywhere from about 10 μm to 150 μm. If the device wafer is thinner than 150 μm it is possible to process the thin wafer through various backside process steps if the thinned wafer is on a carrier wafer.

There are several methods for accomplishing the temporary bonding process. Regardless of the temporary bonding method used, to achieve a thinned device wafer with good process control means the planarity and warp of the complete stack consisting of carrier wafer, plus temporary bonding adhesive, plus the silicon device wafer must be carefully controlled.

Fig1

Silicon wafers are very common in wafer fabrication facilities. A silicon carrier wafer is a very close match to the device substrate wafer. A silicon carrier wafer can be a lower grade wafer and does not have the device specific layers. Thus it may be a good choice as a carrier wafer in development activities. However, as the thinning process for 3D-IC transfers into production it is illustrative to consider other alternatives.

Corning has been providing glass solutions for a variety of industrial and consumer applications for more than 160 years. Among recent applications enabled by Corning’s precision flat glass process technology is the liquid crystal display (LCD) substrate. This platform is an attractive option for development to supply alternative high volume substrate material as a new kind of glass wafer carrier for the semiconductor industry.

上一篇: 无颗粒晶圆清洗干燥技术

下一篇: 硅片金属污染检测技术比较