The cleaning of two-dimensional (2D) materials is an essential step in the fabrication of future devices, leveraging their unique physical, optical, and chemical properties. Part of these emerging 2D materials are transition metal dichalcogenides (TMDs). So far there is limited understanding of the cleaning of “monolayer” TMD materials. In this study, we report on the use of downstream H2 plasma to clean the surface of monolayer WS2 grown by MOCVD. We demonstrate that high-temperature processing is essential, allowing to maximize the removal rate of polymers and to mitigate damage caused to the WS2 in the form of sulfur vacancies. We show that low temperature in situ carbonyl sulfifide (OCS) soak is an effificient way to resulfurize the material, besides hightemperature H2S annealing. The cleaning processes and mechanisms elucidated in this work are tested on back-gated fifield-effect transistors, confifirming that transport properties of WS2 devices can be maintained by the combination of H2 plasma cleaning and OCS restoration. The low-damage plasma cleaning based on H2 and OCS is very reproducible, fast (completed in a few minutes) and uses a 300 mm industrial plasma etch system qualifified for standard semiconductor pilot production. This process is, therefore, expected to enable the industrial scale-up of 2D-based devices, co-integrated with silicon technology.

In the present paper, we investigate the use of a downstream hydrogen plasma for selective removal of PMMA (as a model contaminant) from single layer MOCVD WS2 fifilms. PMMA is used routinely as a flflexible adhesive fifilm for the transfer of 2D materials from one substrate to another; but multiple other polymers are being considered for transfer17. In downstream plasma confifiguration, only long-lived species, namely hydrogen atoms, are allowed to interact with the treated surface. Reactive H atoms are effificient for chemical etching of various polymers13,18,19. However, atomic hydrogen is also known to be reactive towards TMDs. Sulfur vacancy formation upon H exposure of MoS2 and WS2 via H2S release has been reported in experiments20,21 and predicted in simulations22. The main challenge for dry cleaning of WS2 is to avoid sulfur loss while etching polymer residues. In this work, we demonstrate that the substrate temperature is a critical parameter during the cleaning process, since it governs both polymer removal and WS2 damage by reactive H atoms. Lost sulfur can be restored by soaking the S-depleted surface under low-pressure carbonyl sulfifide (OCS) atmosphere.

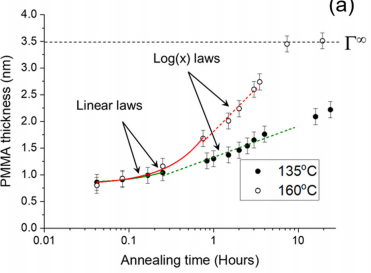

The Fig. 1(b, c) aim at better understanding the removal mechanism of the PMMA, when exposed to a downstream H2 plasma. The evolution of PMMA thickness as a function of the DPS etch time is shown in Fig. 1(b), for three substrate temperatures. The use of scaled coordinates allows to circumvent the large difference in absolute etch rates, and highlight different etch regimes. An overlay is achieved for all three curves at d/dmax ≳ 0.01, i.e., d ≳ 6–10 nm, indicating that the polymer etching, although being different in rate, follows the same linear removal mechanism, i.e., without formation of a top carbon-rich crust slowing down the reaction rate. For a thickness below ~6 nm, a discrepancy appears, where the polymer removal is slower, especially at higher temperatures, 170–250 ∘ C. Another insight is given by Fig. 1(c), showing an Arrhenius plot of the mean removal rate versus temperature. It is found that in the chosen plasma conditions the etch rate of PMMA increases over more than three orders of magnitude, from ~0.06 to ~100 nm/s when the substrate temperature is increased from 60 to 300 ∘ C. This graph allows to discriminate two etch regimes: for T < 120 ∘ C, an activation energy of Ea = 0.64 eV can be calculated, while for T > 120 ∘ C, another etch regime appears with lower apparent activation energy.

From the WS2 cleaning perspective, elevated treatment temperatures ensure higher PMMA removal effificiency, as well as better selectivity towards WS2. Figure 2(b) demonstrates that extended plasma exposure at 300 ∘ C leads to a steady decrease of the PL intensity as a result of defect generation. However, even after 18 s of plasma treatment the overall shape of the PL spectrum remains unaffected, which means that the material retains its structural properties. Remote hydrogen plasma can, therefore, be employed not only for cleaning but also for a soft sulfur vacancy generation in TMD layers. Controllable production of sulfur vacancies is a promising route for doping, chemical activation, or contact engineering in TMDs.

Keeping the substrate temperature suffificiently high is essential to have effificient and selective polymer removal. Etch selectivity can be further improved by tuning the flflux of H atoms. The rate of sulfur vacancy generation via H2S release is proportional to the square of the incoming atomic hydrogen flflux while PMMA decomposition is a fifirst order process and its rate is a linear function of the H flflux19. Hence, the reduction of hydrogen flflux is expected to further improve etch selectivity towards WS2, while minimizing the S vacancy formation.

上一篇: 基板预栅极清洗的系统和方法

下一篇: 局部湿蚀刻法制备硅玻璃凹微透镜阵列