Abstract: A simple and efficient technique for large-area manufacturing of concave microlens arrays (MLAs) on silica glasses with femtosecond (fs)- laser-enhanced chemical wet etching is demonstrated. By means of fs laser in situ irradiations followed by the hydrofluoric acid etching process, large area close-packed rectangular and hexagonal concave MLAs with diameters less than a hundred of micrometers are fabricated within a few hours. The fabricated MLAs exhibit excellent surface quality and uniformity. In contrast to the classic thermal reflow process, the presented technique is a maskless process and allows the flexible control of the size, shape and the packing pattern of the MLAs by adjusting the parameters such as the pulse energy, the number of shots and etching time.

During the last decade, some techniques for the fabrication of concave MLAs have been proposed. For example, a concave refractive microlens array was fabricated in solgel glasses by a proximity-effect-assisted reflow technique, which was proposed in 2004 [14]. Later on, Ruffieux and associates developed a two-step process for fabrication of diffraction limited concave microlens arrays [11]. First, cylindrical holes were produced by the photolithograph method followed by a melting step preformed at 150°C for half an hour; the melted structures were then filled by a second spinning step of photoresist. Other techniques such as 3D diffuser lithograph and “breath figures” method [15,16], which were employed to fabricate concave molds, can also fabricate the concave MLAs. Moreover, through the reversal replication technique, the concave MLAs could be produced by the convex MLAs. We notice that most approaches to the fabrication of concave MLAs are based on the process using the photomasks, which are very expensive. The maskless processes such as LDW are complex and inefficient, which are not suitable for the large area fabrication of concave MLAs. Herein, a simple, high-efficient maskless technique for the concave MLAs is developed using a femtosecond (fs) laser-induced crater arrays followed by a chemical etching process. This method simplifies the classic laser etching process [17,18], improving the fabrication efficiency significantly. In addition, it allows direct manufacturing of various concave MLAs on glasses, which have better physical and chemical properties than the photoresist, polymethylmethacrylate (PMMA) or polydimethylsiloxane (PDMS), and more importantly, the reflection loss of lights caused by the interfaces between the polymer layers and substrates is not exist. Other advantages, such as simple process, facile processing environment and flexible control of the size, the packing pattern and the shape of the MLAs by adjusting some parameters, are also demonstrated.

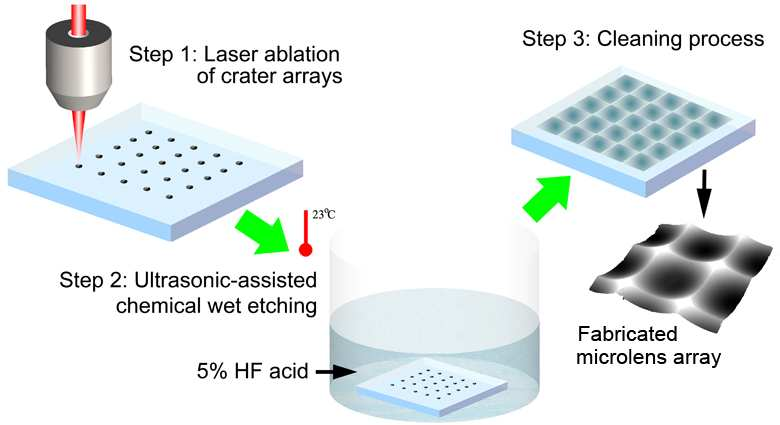

The rectangular and hexagonal-packed concave MLAs are fabricated by a three-step process, as depicted in Fig. 1. Initially, ablation-induced craters with diameters of a few micrometers are induced on polished silica glass chips (10 × 10 × 1 mm3 , China Daheng Group Inc., GCL- 1202) using a 30-fs and 800-nm laser pulses at a repetition of 1 kHz (the laser source is a Ti: sapphire pulsed laser oscillator-amplifier system). The femtosecond laser, owing to its advantages of negligible thermal and shockwave-induced damages [19], when focused by an objective lens (NA = 0.5), can easily induce craters on transparent materials such as silica glasses without melting-ejections and cracks which will impact on the morphology of the fabricated microlenses. The diameter of the focal spot is about 1.4 µm (1/e). The pulse energy can be varied by a variable neutral density filter and the number of shots is controlled by a shutter. More details of the setup used here can be found in Ref [20]. Subsequently, the samples with craters are treated in 5% hydrofluoric (HF) acid solution assisted by an ultrasonic bath at 23°C. During this process, the chemical etching velocity is accelerated in the laser-induced craters and the concave spherical surfaces begin to form; the MLAs are consequently fabricated in tens of minutes. Finally, the samples are cleaned by the ultrasonic bath in acetone, alcohol and deionized water for 15 minutes, respectively, and dried in ambient air.

Fig1

In the experiment, the whole fabrication process is monitored by an optical microscope (OM) equipped with a CCD camera. Figure 2 shows the evolution of the rectangular and hexagonal MLAs changing from the laser-induced crater arrays. In the beginning, the isotropic chemical etching occurs in the laser treated points [black dots shown in Figs. 1(a) and 1(d)], producing circular-shaped concave structures in the rectangular [Fig. 1(b)] or hexagonal [Fig. 1(e)] patterns, which can serve as the circular MLAs. Then the aperture diameter of the circular microlenses expands gradually with the chemical etching, and eventually, the adjacent ones “overlapped” with each other, resulting in the formation of the tetragonal and hexagonal shaped microlenses, as shown in Figs. 1(c) and 1(f). It demonstrates that the packing pattern and the shape of the microlenses can be easily controlled by the arrangement of the laser irradiated points and the chemical etching time. The areas of the fabricated rectangular and hexagonal MLAs are about 3 × 3 mm2 and 1.5 × 1.5 mm2 , respectively, and the whole processing time is about 3 hours, which is more efficient than the LDW process [20]. Figures 3(a) and 3(b) show the SEM images of the rectangular and hexagonal MLAs, respectively. They visually express the excellent surface quality and uniformity of the MLAs.

To evaluate the focal length of the MLAs, fexp, an optical system equipped with a He-He laser (633 nm), a computer-controlled stage, a lens and a CCD camera, is built up, as shown in Fig. 5. Moving the computer-controlled stage along the direction parallel to the laser beam (zaxis), the position of the top surface and the focal point can determined by the images captured by the CCD camera. The values of fexp are obtained by equation, fexp = L - h, where L is the distance between the focal point and the top surface of the MLAs. The focal length of the rectangular and the hexagonal MLAs is 125.0 ± 5 µm and 84.0 ± 5 µm, respectively. These values match well with the calculated focal length, fcal, which are obtained by equations: fcal = R/[n-1] (2), where n denotes for the refractive index of the silica glass at wavelength of 633 nm. Considering n = 1.45, the values of fcal are 128.80 µm and 81.06 µm for the rectangular and hexagonal MLAs. Furthermore, the values of numerical aperture, NA, for both MLAs are calculated by equation: NA = D/2f (3), and the results are 0.26 and 0.19, respectively. The experimental results are summarized in Table 2.

上一篇: 过渡金属二硫属化物单层的反应等离子体清洗

下一篇: InP 中对准 V 型槽的湿法化学蚀刻