The temperature dependence of the Si~ 100! /XeF2 etch reaction is studied quantitatively in a molecular beam setup. At a sample temperature of 150 K the reaction probability reaches unity initially, after which the XeF2 condenses on the surface and blocks the etching process. For increasing temperatures the XeF2 reaction probability initially decreases from 100% at 150 K down to 20% around 400 K, but for temperatures above 600 K it increases again up to 45% at 900 K. In a simple reaction scheme the high etch rate at low temperatures is explained by a XeF2-precursor, with an activation energy for desorption of 326 4 meV. Furthermore the increased etch rate at high temperatures is explained by the desorption of SiF2 with an activation energy of 2606 30 meV. The steady-state flfluorine content of the SiFx reaction layer, measured using thermal desorption spectroscopy, reaches a maximum of 5.5 monolayers at 300 K. For increasing temperatures it decreases to a submonolayer coverage above 700 K. The temperature dependence of the formation of the reaction layer is described well by including the XeF2-precursor in a previously developed adsorption model. © 1996 American Vacuum Society.

Plasma etching is one of the most important steps in the fabrication process of integrated circuits, and flfluorine is the main etchant in many of these plasmas. Therefore many surface science studies have been devoted to the interaction of flfluorine species with silicon, in order to unravel the fundamental physics and chemistry of the etching process.

So far most temperature dependence studies of the Si/XeF2-reaction have concentrated on the product distribution. It was shown by Dagata et al.11 that above 600 K SiF2 becomes a signifificant etch product. Experiments in our setup7 showed that this is accompanied by an increase in the XeF2 reaction probability to a value of 50% at 900 K and a slight decrease in the SiF4-production. In the temperature range from 300 to 1000 K, Winters and Coburn1 observed a minimum in the reaction probability around 400 K. A similar effect was observed by Ibbotson et al. 12 but it is hard to compare this experiment with the beam work because it was done in a completely different ~ non-UHV! regime, using a XeF2 pressure of 102 1 Torr. No data have been reported for sample temperatures below 260 K.

Few experiments were done to study the temperature dependence of the steady state reaction layer. Bermudez13 observed, using infrared reflflection absorption spectroscopy, that between 300 K and 550 K the reaction layer consists of SiF-, SiF2- and SiF3-species, while at higher temperatures the SiF-coverage increases as other species decompose. Using Auger electron spectroscopy ~ AES! and XPS, Chuang14 found that XeF2 chemisorption on Si is still dissociative at 2 150 °C.

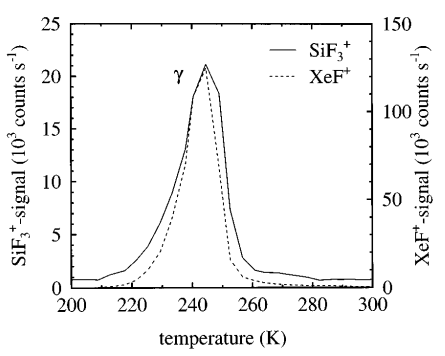

Fig1

The high temperature data are displayed in Fig. 6. For comparison the 300 K data of Fig. 5 are repeated. The flfluorine content is seen to decrease with increasing temperature, but the qualitative behavior of the 400 K, 500 K and 600 K data is very similar to what was observed at room temperature. At 700 K the flfluorine content seems to saturate almost immediately. Above 700 K the desorption signal was too weak to allow a study of the dose dependence.

We observe in Fig. 5 that for 250 K and 200 K the initial growth of the reaction layer is much faster than at room temperature. Furthermore, especially for the 200 K data, the reaction layer seems to saturate at a much lower XeF2-dose and flfluorine content. The 175 K data show a different behavior. The fast initial growth rate is followed by a linear increase in the flfluorine content. As was shown in the previous section, this can be explained by XeF2-condensation on the surface.

The Si/XeF2-etch rate shows a complex temperature dependence. As the temperature is increased from 150 K, it initially decreases, reaches a minimum around 400 K and subsequently increases ~ Figs. 7 and 9! . The minimum around 400 K has also been observed in the experiments at room temperature and above by Ibbotson et al.12 and by Winters and Coburn.1 Both studies attribute the increased etch rate at temperatures below 400 K to a reaction mechanism involving a XeF2-precursor. This seems reasonable considering the low temperature effects observed in our experiments. Ibbotson et al.12 suggest that the increase at high temperatures is caused by a change in the reaction mechanism towards direct impact dissociation of the XeF2. However, we observed that the increase in the etch rate at high temperatures is correlated with the breakdown of the SiFx reaction layer ~ Fig. 4! and the production of SiF2 ~ Fig. 9! . Therefore we suspect that the desorption of SiF2, and thus the increase in reactive sites at the surface, is the actual cause of the increased etch rate at high temperatures.

上一篇: n型多孔硅刻蚀时间的效应