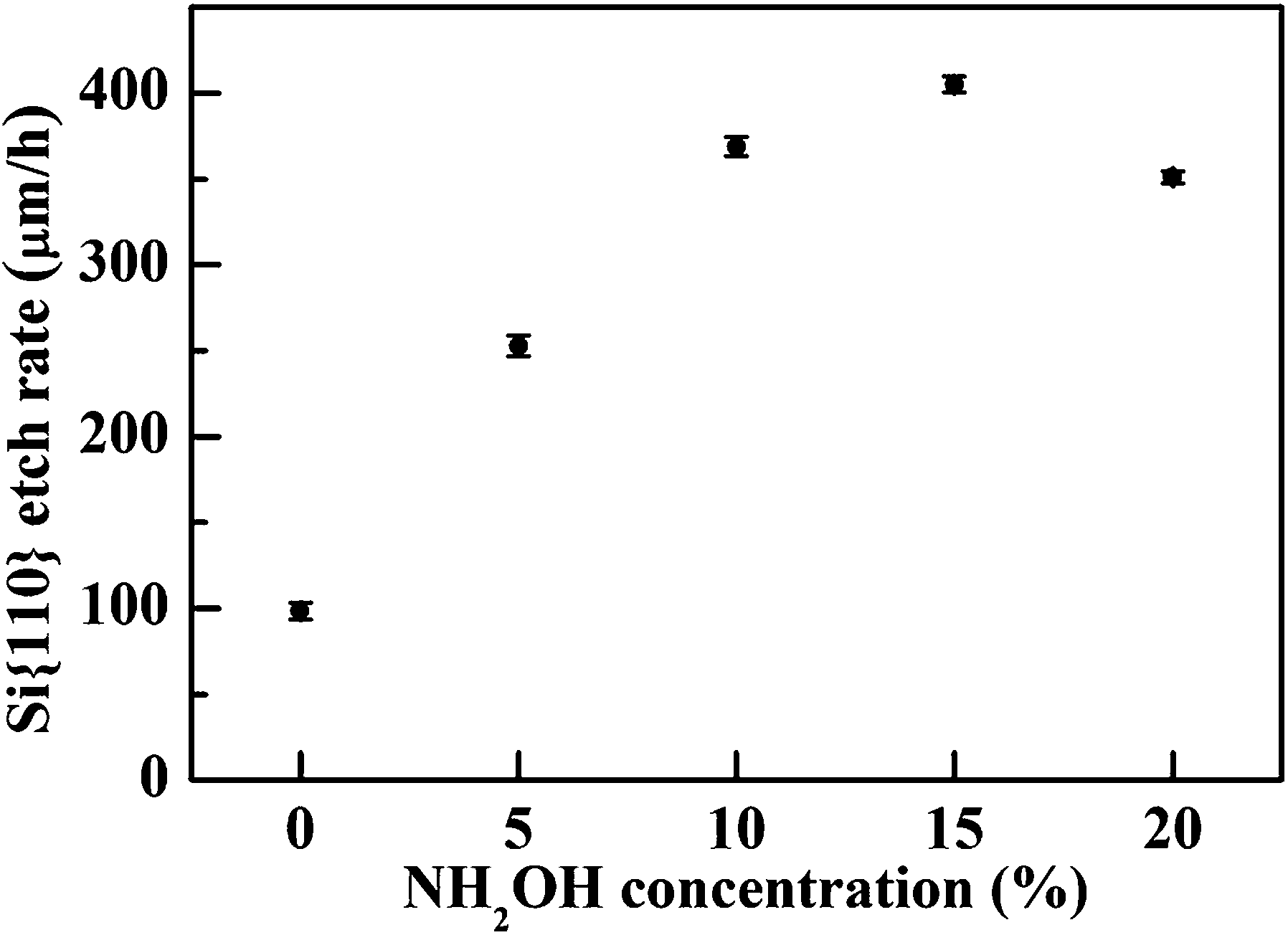

Anisotropic wet etching is a most widely employed for the fabrication of MEMS/NEMS structures using silicon bulk micromachining. The use of Si{110} in MEMS is inevitable when a microstructure with vertical sidewall is to be fabricated using wet anisotropic etching. In most commonly employed etchants (i.e. TMAH and KOH), potassium hydroxide (KOH) exhibits higher etch rate and provides improved anisotropy between Si{111} and Si{110} planes. In the manufacturing company, high etch rate is demanded to increase the productivity that eventually reduces the cost of end product. In order to modify the etching characteristics of KOH for the micromachining of Si{110}, we have investigated the efect of hydroxylamine (NH2OH) in 20 wt% KOH solution. The concentration of NH2OH is varied from 0 to 20% and the etching is carried out at 75 °C. The etching characteristics which are studied in this work includes the etch rates of Si{110} and silicon dioxide, etched surface morphology, and undercutting at convex corners. The etch rate of Si{110} in 20 wt% KOH + 15% NH2OH solution is measured to be four times more than that of pure 20 wt% KOH. Moreover, the addition of NH2OH increases the undercutting at convex corners and enhances the etch selectivity between Si and SiO2.

In all kinds of wet anisotropic etchants, Si{111} planes exhibit minimum etch rate. If the mask edges are aligned along the directions comprises {111} planes, wet anisotropic etching provides microstructures with smooth sidewalls due to the emergence of {111} planes at these directions. Te angle between sidewall and wafer surface depends on the wafer orientation. Moreover, the number of directions along which {111} planes appear depend on the orientation of wafer surface. In the case of {100} wafer, four {111} planes making an angle of 54.7° with wafer surface expose at ⟨110⟩ directions. Hence {100} wafer is suitable to fabricate rectangular shaped cavities or suspended structures over rectangular shape cavity using wet anisotropic etching [3, 6, 12, 21]. In the case of the wafer with {110} surface, two slanted planes making an angle of 35.5° with wafer surface and four vertical planes with respect to wafer surface appear along ⟨110⟩ and ⟨112⟩ directions, respectively. Terefore, in order to fabricate microstructures with vertical sidewalls {110} wafer is a most appropriate choice [10, 28–34]. It can be used to fabricate deep channels/cavities with vertical sidewall.

In this paper, we have studied the etching characteristics of {110}-oriented silicon wafer in 20 wt% KOH solution without and with addition of NH2OH. It is mainly focused to investigate the efect of NH2OH in 20 wt% KOH to achieve improved etching characteristics for applications in silicon bulk micromachining for the formation of MEMS structures.

Etching characteristics of Si{110} including etch rate, surface roughness/morphology, and undercutting at convex corners are studied on the samples etched in pure and NH2OH-added 20 wt% KOH. To study etching characteristics, the concentration of NH2OH is varied from 5 to 20% in steps of 5%. Detailed descriptions of these characteristics are presented in following subsections.

Fig1

Surface morphology is one of major concerns in optical MEMS applications and designing high-efciency solar cell, etc. Etched surface morphology primarily depends on the etchant type, etchant concentration, etching temperature, additives, and agitation of etchant during etching process. Te average etched surface roughness decreases with the increase of etching temperature and KOH concentration . Surface roughness of the samples etched in 20 wt% KOH solution without and with addition of various concentrations of NH2OH is measured using 3D measuring laser microscope (Olympus, OLS4000) and presented in Fig. 4. Te standard deviation indicated by error bars is calculated by taking six measurements on the same sample at diferent locations. Figure 5 presents SEM images of the etched samples corresponding to surface roughness shown in Fig. 4. Average surface roughness (Ra) of the samples etched in NH2OH-added 20 wt% KOH solution is nearly same as those are etched in pure 20 wt% KOH. It means that the etched surface of Si{110} is not afected signifcantly when NH2OH is added into KOH solution. Main cause of surface roughness in the wet etching process is micromasking by the hydrogen bubbles and/or impurities on the surface during the etching process .

Etching characteristics of Si{110} surface in pure and diferent concentration of NH2OH-added 20 wt% KOH are studied for applications in silicon wet bulk micromachining. Te etching characteristics of KOH solution are changed drastically when NH2OH is added. Te etch rate and undercutting are improved signifcantly. High etch rate is very useful to achieve larger etch depth in less time in comparison to common etchant. Increase in undercutting at convex corner is benefcial for the fast release of the microstructures. Both these characteristics are indispensable for reducing etch time and therefore useful for industries to increase the productivity. Moreover, NH2OH-added KOH provides high etch selectivity between silicon and oxide (i.e. Si/SiO2) in comparison to pure KOH. High etch selectivity can be exploited for the fabrication of MEMS structures using silicon dioxide as mask/structural layer. It can be concluded that the results presented in this paper are highly useful for research and industrial applications.

上一篇: Si蚀刻:温度依赖性

下一篇: Si晶片表面上由Si面形成的角的蚀刻特性