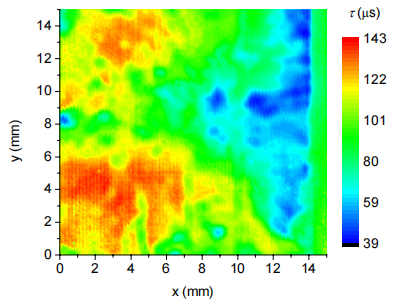

We found that organic particle contaminants are effectively removed during ultrasonic cleaning in distilled water, as evidenced by the disappearance of organic-related absorption peaks and remarkable shortening of the surface photovoltage decay transients (SPV). SPV decay transient mappings obtained with a 100-µm spatial resolution (see abstract figure) show that, in multicrystalline Si wafers, the resulting effect on the decay time is markedly non-uniform compared with that observed in crystalline Si, implying the existence of a mechanism associated with the grain boundaries. The data are tentatively interpreted in terms of the wafer hydrogenization, which most probably occur through the grain boundaries. It is assumed that elevated temperatures inside a cavitating bubble may lead to water and bubble gas decomposition, accompanied by a subsequent trapping of the decomposed particulates at the silicon surface. These particulates can then be predominantly incorporated into the grain boundary regions. We suggest that this can be in part due to hydrogen molecules decomposed in water which are mobile in silicon.

In recent years, the usage of renewable energy sources like solar cells and panels has increased remarkably. Among installed photovoltaic systems, more than 90% are mono- and polycrystalline silicon cells, which provide the advantages of low cost and large area with relatively high efficiency. Cleaning the surfaces of silicon wafers is one of the most critical operations in device processing technologies , in particular, in the photovoltaic industry.

In this context, among other techniques, ultrasonic agitation is widely used to adding energy into the wet cleaning bath. Planar and patterned silicon wafers are routinely cleaned using ultrasonic waves. In this process, the wafers are immersed in a chemically active solution subjected to high power beams of acoustic waves. Sonochemical cleaning has proved to be particular effective, e.g., after pre-oxidation, pre-chemical vapor deposition, pre-epitaxial growth, postash and post-chemical mechanical polishing of Si wafers.

It is commonly believed that the cleaning removes contaminating additives from the wafer surface through acoustic cavitation and acoustic streaming although the physics behind the ultrasonic-induced cleaning process is still not completely understood and the precise cleaning mechanisms are still the subject of debate. The frequency range of the waves used in this process is rather wide, typically in the kHz–MHz range. A combination of induced streaming flows in the cleaning solution, acoustic cavitation, the level of dissolved gases and oscillatory effects are thought to contribute to removing particles and complex organic materials from the wafer surface.

Here, we report the photovoltaic behavior of poly- and monocrystalline Si wafers subjected to a surface cleaning process in ultrasonically agitated distilled water. We concentrate on studying the surface photovoltage (SPV), measuring the variation of surface potential upon illumination.

In this context, among other techniques, ultrasonic agitation is widely used to adding energy into the wet cleaning bath. Planar and patterned silicon wafers are routinely cleaned using ultrasonic waves. In this process, the wafers are immersed in a chemically active solution subjected to high power beams of acoustic waves. Sonochemical cleaning has proved to be particular effective, e.g., after pre-oxidation, pre-chemical vapor deposition, pre-epitaxial growth, postash and post-chemical mechanical polishing of Si wafers.

It is commonly believed that the cleaning removes contaminating additives from the wafer surface through acoustic cavitation and acoustic streaming although the physics behind the ultrasonic-induced cleaning process is still not completely understood and the precise cleaning mechanisms are still the subject of debate . The frequency range of the waves used in this process is rather wide, typically in the kHz–MHz range. A combination of induced streaming flows in the cleaning solution, acoustic cavitation, the level of dissolved gases and oscillatory effects are thought to contribute to removing particles and complex organic materials from the wafer surface.

上一篇: 兆声波技术进行TSV蚀刻后清洗工艺

下一篇: 各种薄膜颗粒有效湿清洗方法的评价