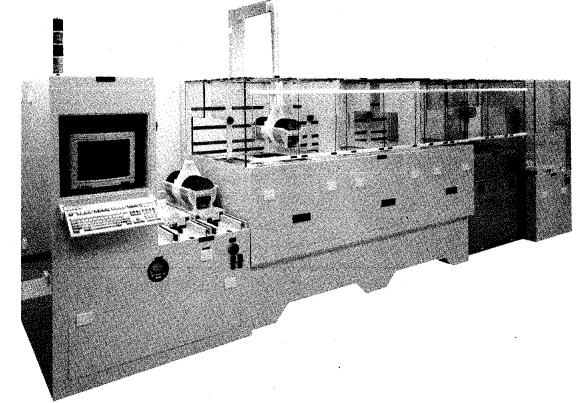

There are two principal methods of cleaning wafers: gas-phase - dry cleaning - (Figs. 1 & 2) and liquid phase - wet cleaning - (Figs. 3 & 4.) Although the respected “standard clean,” the RCA wet clean, continues its foothold, other technologies, including dry methods, are beckoning to users.

Dr. Werner Kern, then at RCA Laboratories, devised the RCA clean for RCA’s use in 1965. He detailed the process publicly five years later. (Table 2). This two-step clean is an oxidizing and complexing treatment. It employs aqueous H202 - NHIOH and Hz02 - HC1 mixtures at 75-80°C for 10 min.

The use of advanced wetchemical cleaning for making ultrapure silicon wafers will persist for several more years, ‘ says Kern. The trend, however, 7 is from liquid to gaseous reac- 7 tants.

“Eventually and ideally,” Kern adds, the entire cleaning sequence will be conducted in situ by a sequence of gas phase reactions at low or reduced pressure with elevated temperature. This will take place in a cluster tool integrated with other cluster modules for film deposition, annealing, dry etching and other fabrication steps.

He doesn’t expect dry cleaning to replace wet cleaning, except in applications where wet cleans cannot be used. tinue to be important, other factors - surface roughness, surface termination and oxide and growth characteristics - need to be completely understood, Deal says. Not only that, but cleaning success will increasingly be “based on electrical test as opposed to particles and metals.’’

In fact, Deal, whose firm is one of the largest suppliers of cleaning equipment, calls for a “holistic approach’’ to wafer cleaning needs. This means that the relationship between cleaning and the process steps prior and after must be understood and development completed together.

Tomorrow’s problem, being generally recognized today, is the difficulty of removing smaller particles in the 0.1 pm (and smaller) range, adds Robert Donovan of Research Triangle Institute. Most of today’s particle removal technology becomes less effective, Donovan adds, as particle size decreases.

The future of cleaning development will rely on application-specific uses, says Dr. Donald Deal, chief technologist for FSI International. Each clear., Deal adds, will have specific requirements dictated by the subsequent processing step. The variation in these requirements will cause a variation in the clean technology, sequencing and tool that the process engineer selects. This, Deal contends, will lead to variations in chemical sequence, chemical concentrations and changes to new chemistries. The bottom line: “All basic cleaning technologies, wet, vapor or dry, will be required and used either separately or in combination.”

Fig1

Wet cleans, based on the RCA clean, will not soon disappear, despite some hardy band pushing for their elimination. Dry cleaning techniques, as Motorola’s DePinto notes, “are pretty application-specific.”

Typically,” says Micron’s Paduano, “alternative cleaning methods have not been implemented where high throughput is needed.” Look for the use of both wet and dry cleans to become quite application-specific and to work side-byside.

上一篇: 用于单晶片清洗的超临界流体