Abstract—In this study, various cleaning solutions containing chelating agents with carboxyl acid group ( COOH), such as ethylenediaminetetraacetic acid, citric acid and oxalic acid, were developed for post-poly-Si CMP cleaning. The chelating agent and tetramethylammonium hydroxide (TMAH) were simultaneously added into 2% ammonium hydroxide alkaline solution to promote the removal efficiency on particles and metallic impurities. The effectiveness of various cleaning recipes and their interaction mechanism with poly-Si surface were studied. We could explain the surface behavior of various cleaning solutions by the different molecular size and charge of chelating agents. Based on the mechanism, the behavior of surface particle and metallic impurity can be realized. The co-existence of TMAH with citric acid or oxalic acid in the alkaline cleaning solutions can significantly enhance the electrical property for the capacitor.

The particle deposition on a hydrophilic wafer surface is a strong function of the pH value in the solution. Larger than pH 10 results in low particle deposition [6]. Numerous methods have been developed to improve the efficiency of removing particle. The most effective commercial method is the megasonic cleaning process [7]. The SC-1 solution in coupling with the megasonic cleaning process can remove organic and inorganic particles from surface at specific temperature ranging from 25 ℃ to 75 ℃ in the semiconductor industry. The particle cleaning process is very useful in cleaning after CMP process to remove the slurry on the poly-Si surface. In megasonic systems, the energy is produced by an array of piezoelectric crystals or transducers. These wafers carried with cassettes are immersing in the clean tank, such as SC-1 solution. The impact of high-frequency (700–1000 kHz) sonic pressure waves on the wafers enhances the cleaning ability for the cleaning solutions. The force required to remove a particle from the wafer surface must be equal to (or exceed) the force of particle adhesion. In addition to particle removal, the megasonic process with SC-1 also demonstrates the capability to remove the copper contamination . This observation is due to the readily exchange of copper ions with ammonia (NH ), and the metallic impurities can be rinsed off.

A previous paper has reported the following problem for post-CMP cleaning on poly-Si film, both abrasive and metallic contaminant were left on the hydrophobic poly-Si surface and could not be removed with high efficiency in alkaline cleaning solutions. Up to now, the most effective way to remove particles from the polished poly-Si film can be achieved by using the diluted ammonium hydroxide solution. The particle removal mechanism is based on slightly etching the wafer surface, thus electrostatic repulsion is formed between the particle and wafer surface due to the negative potential. The tetramethylammonium hydroxide (TMAH) has been used to increase the particle removal efficiency . However, metallic impurities tend to adhere on poly-Si surface after the cleaning with alkali solution. Our previous study has found that the simultaneous spiking of TMAH and chelating agents in the cleaning solutions can effectively prevent the contamination problem of various metallic impurities on the poly-Si surface, [10]. The removal efficiency of particles and metallic impurities and the electrical characteristic after cleaning can be significantly improved by using this novel solution.

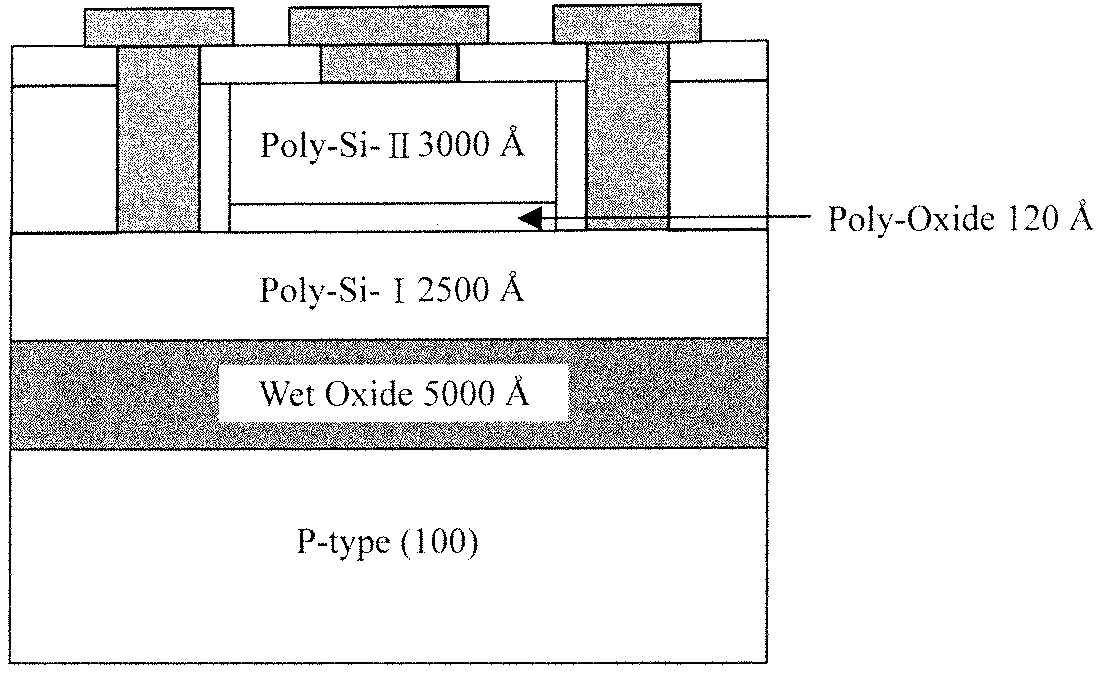

Fig1

In the paper, various cleaning solutions containing chelating agents with carboxyl acid group (-COOH) were explored for their influences on the surface roughness of poly-Si-I. We found the removal efficiency of particle and metallic impurity and the electrical characteristic can be significantly improved for postpoly-Si CMP cleaning by using these novel solutions. By adding the TMAH and chelating agent (citric acid with 200 ppm) into 2% ammonium hydroxide (NH OH) alkaline aqueous solution, the residual metallic impurities and particles on the wafer surface and the electrical characteristics of poly-oxide capacitors are significantly improved for post-CMP cleaning.

Fig. 5 shows the metal concentrations measured with TXRF instrument. It is very clear that the metallic contaminants are significantly removed by using the novel solutions, especially for the removal of K, Ti, Cr, and Fe ions. The chelating agent reacts with metal ion as in the forms of metal-chelate complex. This reaction prevents the precipitate on the poly-Si surface in a form of metal hydroxide during high pH solution. It clearly demonstrates that cleaning solution B is not suitable to remove the metals of K and Ti. This finding can be also explained from the mechanism appearing in Fig. 4 that the bulky EDTA can hardly react with the trap metal ion on poly-Si surface due to the lower ratio of charge to size. Solution C shows the better removal efficiency on metal than C , indicating the concentration effect of chelating agent. Fig. 5 demonstrates the higher amount of chelating agent is beneficial for metal removal. However, the cost and the chelating agent contamination need further evaluation.

上一篇: 硅光子芯片上的微波信号切换