The demand for increased functionality and performance of electronic devices is called for by the 30 % shrink and double device density every 2 years by the International Technology Roadmap for Semiconductors (ITRS) guidelines. Photolithography processing steps are key technology modalities that allowed continuous cost reduction per transistor with increasing device complexity. Currently, 193 nm optical lithography’s K1 is well below 0.4 increasing process complexity and cost of overall photolithography process significantly. Extreme ultraviolet (EUV) lithography remains an option for the sub-32 nm nodes, capable of offering K1 >0.4 for 32 nm / 22 nm nodes with optics of numerical aperture (NA) 0.25. However, developing a photoresist capable of meeting the needs of dose sensitivity, resolution, and line width roughness (LWR) remains challenging. The ITRS requires that the 32 nm and 22 nm nodes achieve LWR (3V ) of 1.7 nm and 1.2 nm, respectively with dose sensitivity of (5 to 15) mJ/cm2 . In order to understand trade-offs among dose sensitivity, LWR, and resolution, a study of combined effects of latent image formation and development image using a model EUV photoresist system is desired.

A model EUV photoresist system with reduced formulation parameters (without base quencher) simplifies the study of latent image to developed image formation under controlled conditions. We have selected and customized a model photoresist consisting of poly(hydroxystyrene-co-tert-butyl acrylate) 1 . Our previous studies of acid diffusion in this model photoresists polymer have shown that the spatial extent of deprotection profile increases with increasing dose or acid concentration, but it is self limiting into the unexposed regions of photoresist even without the use of base quencher2,3 . We investigate the effect of PAG loading and developer strength on EUV pattern fidelity.

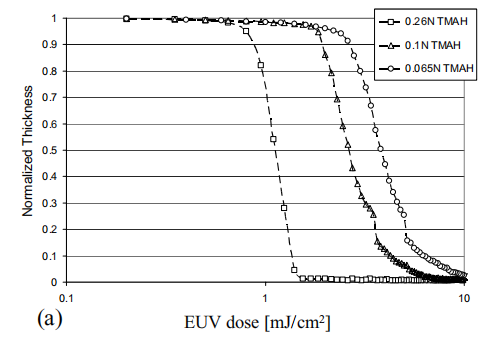

The model photoresist used was poly(hydroxystyrene-co-tert-butyl acrylate) (P(HOSt-co-tBA)) (number average relative molar mass (Mn) = 11,459 g/mol, polydispersity index (PDI) = 1.83, containing 49 % by mole HOSt and 51 % by mole tBA (DuPont Electronic Polymers). The photoacid generator used was triphenylsulfonium perfluorobutane sulfonate (TPS-PFBS) (Sigma-Aldrich). The P(HOSt-co-tBA) was dissolved at a concentration of 5 % by mass in propylene glycol methyl ether acetate (PGMEA) with various PAG loadings ranging from 3 % to 15 % by mass of copolymer. Tetramethylammonium hydroxide (TMAH) solutions with developer strengths of 0.065 N, 0.1 N, and 0.26 N were prepared by diluting a 25 % (by mass) stock solution (Aldrich) with deionized water purified and filtered by a Milli-Q system (Millipore). There were no other additives included in this model photoresist and developer solution allowing a controlled study of the effect of PAG loading and developer strength. When referring to the PAG loadings (or concentration) it will be implied as % by mass from this point forward.

The model photoresist with PAG loadings of 3 %, 5 %, 10 %, 15 % of copolymer were spin coated onto silicon wafers that were treated by hexamethyldisilazane and post-apply baked (PAB) at 130 °C for 60 s. The average film thickness after PAB was 100 nm. The model photoresist samples of various PAG loading were then exposed using the 0.3 NA EUV micro-field exposure tool (MET) at the Advanced Light Source (ALS) of Lawrence Berkeley National Laboratory (LBNL) 4,5 using a standard ALS MET EUV reticle’s bright-field test patterns with annular illumination (0.3 to 0.55). A fixed post-exposure bake (PEB) at 90 °C for 30 s was performed.

Fig1

We have demonstrated patterning capabilities of a model EUV photoresist system. This is the first step to study aqueous hydroxide development effects on well-defined latent images to final patterns and may lead to clarify sources of resolution limits and identify processing strategies for resolution improvement. Using a series of PAG loadings and developer strengths comparison correlation experiments were performed. It was demonstrated that higher PAG loading combined with a lower TMAH developer strength help lower LWR in our model EUV photoresists. We did not observe performance issues with highest PAG loading (15 %). The line formation was preceded by initiation of holes and pockets which may be related to latent image or development effects. Further examination and correlation of these holes/pockets formation to the final line edge fidelity may help to understand and identify strategies required for further LWR improvement in polymeric chemical amplified photoresists. In summary, using a model EUV photoresist system, we have demonstrated a feasibility of alternative optimizations for a given formulation through PAG loading and development process tuning.

上一篇: 聚硅薄膜上的CMP后新型清洁解决方案

下一篇: 过氧化氢:可持续发展的关键化学品