Wafer-level chip scale packages (WLCSPs) certainly rank among the key enablers of smaller, thinner, higher functionality devices that are driving advances in mobility, integration and expansive connectivity (IoT). Undoubtedly, the mobile phone and tablet markets have been the primary catalyst for the growth in WLSCP packages in recent years, though there are several other applications that benefit from the thinner, higher-density ball count capabilities of modern-day WLCPS. No doubt mobile phones and tablets will remain important consumers of WLCSPs, but the trend toward prolific connectivity through wearable devices, among other technologies, will help fuel the 6-7% [1] annual growth rate projected for WLCSPs over the next five years.

With the decreasing dimensions and finer ball pitches come increasing wafer processing and handling challenges. Die chipping, die cracking, wafer warpage and package damage during the SMT placement process onto the PCB substrate are all potential obstacles that have to be overcome for high-yield WLCSP production. Recent advances in film technology have resulted a class of materials that help alleviate some of the traditional WLCSP handling and reliability challenges. Backside protection (BSP) films offer packaging subcontractors a technique that helps reduce mechanical damage, while improving laser marking performance and reliability.

Some of the more notable semiconductor packaging film innovations in recent years have come from Henkel. The industry’s first conductive die attach films were introduced by the materials leader almost a decade ago, while other significant film successes include thermal formulations and non-conductive die attach materials. Leveraging the company’s know-how in film formulation, Henkel has developed a series of Backside Protection (BSP) films to enable production of today’s WLCSP devices. With advantages over other commercialized BSP materials, Henkel’s LOCTITE ABLESTIK BSP 1000 is facilitating production of today’s highly miniaturized (< 5 mm x 5 mm) WLCSP devices.

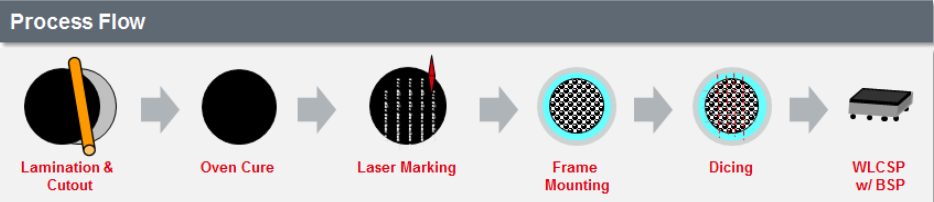

Fig1

Currently available in three different standard thicknesses* -- 25 µm, 40 µm and 100 µm – LOCTITE ABLESTIK BSP 1000 can accommodate various bondline requirements and helps eliminate the need for subsequent mold compound processes. The material is black in color, which not only promotes high visibility of laser markings, but also serves to block light and provide surface protection, helping to keep the circuit surface free from any handling damage.

One of LOCTITE ABLESTIK BSP 1000’s primary competitive advantages is its excellent reworkability on both 8” and 12” wafers. In the event that the film needs to be removed from the wafer, LOCTITE ABLESTIK BSP 1000 is easily peeled off the wafer, leaving no residue. The packaging subcontractor can then reapply the film as per the process noted above. In testing, competitive materials -- particularly with respect to 12” wafers -- have shown removal difficulty which can result in wafer damage or the requirement for subsequent cleaning steps.

As for its laser marking clarity, LOCTITE ABLESTIK BSP 1000 has exhibited excellent laser marking performance both prior to cure and after reflow, as shown below. This is critical, as the device ID is essential to inventory management, quality control and process tracking.

上一篇: LED光刻技术快速制造微流控芯片

下一篇: 两步电镀铜工艺