The Nanostructured materials like nanotubes, nanowires, nanorods, and nanobelts etc. have remained the subject of interest these days because of its unique thermal, mechanical and optical properties. Zinc Oxide (𝑍𝑛𝑂), is the most attractive material due to its unique properties and availability of a variety of growth methods. At nanostructured level, the properties of 𝑍𝑛𝑂 can be altered by controlling the growth process, such as the shape, size, morphology, aspect ratio and density control. In this work, Aligned 𝑍𝑛𝑂 Nanowires (NWs) were successfully synthesized by Chemical Vapor Deposition (CVD) on Aluminum doped Zinc Oxide (AZO) substrate. The effects of different growth parameters such as growth temperature, flow rate of oxygen and distance of substrate from source on growth of aligned 𝑍𝑛𝑂 NWs have been investigated and discussed in detail. Morphologies and structures of grown nanowire arrays were characterized by Scanning Electron Microscopy (SEM) and X-ray diffraction (XRD). Optical properties were optimized by UV-visible transmittance spectra, and photo luminescence (PL).

The diameter and density of nanowires were controlled by the distance between substrate and source. After the growth, the tube furnace was cooled down to room temperature.

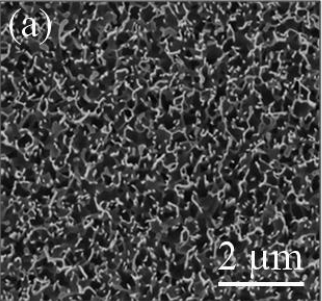

In CVD process, morphology and the structure of a final product can be controlled by the temperature and the level of super-saturation. Generally, for the growth of nanowire arrays, the growth direction and rate are two important factors which determine whether a nanowire can be formed. However, the growth rate mainly depends on the growth temperature . In order to study the effect of temperature on 𝑍𝑛𝑂 nanowire arrays, we used three different temperatures i.e. 540°𝐶 , 560°𝐶 and 580°𝐶 . The growth parameters are illustrated in Table-1, and the morphologies of these samples were analyzed by SEM shown in Fig.1.

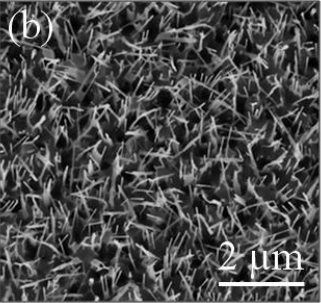

In order to study the effect of oxygen flow on the growth of 𝑍𝑛𝑂 nanowires, we used different flow rates as 8 𝑠𝑐𝑐𝑚, 9 𝑠𝑐𝑐𝑚 and 10 𝑠𝑐𝑐𝑚 oxygen flows. Growth parameters are listed in Table-2, and the SEM images are shown in Fig.2. From the figure we can see that well aligned nanowires were grown for these three parameters, and in this case, the oxygen flow has little effect on the diameter and relatively density. As we know, nanowire diameter and density are crucial for coating the shell layer on 𝑍𝑛𝑂 nanowires. If the density is too high or the diameter is too large, it will be difficult to deposit a shell layer around the entire 𝑍𝑛𝑂 nanowires. For low density or small diameter, the shell deposition is easier but it reduces light absorption which degrades the efficiency of device. By changing the flow rate we can control the density of nanowires, and can get a favorable condition for the growth of coaxial nanowires.

Fig1

In order to study the effect of oxygen flow on the growth of 𝑍𝑛𝑂 nanowires, we used different flow rates as 8 𝑠𝑐𝑐𝑚, 9 𝑠𝑐𝑐𝑚 and 10 𝑠𝑐𝑐𝑚 oxygen flows. Growth parameters are listed in Table-2, and the SEM images are shown in Fig.2. From the figure we can see that well aligned nanowires were grown for these three parameters, and in this case, the oxygen flow has little effect on the diameter and relatively density. As we know, nanowire diameter and density are crucial for coating the shell layer on 𝑍𝑛𝑂 nanowires. If the density is too high or the diameter is too large, it will be difficult to deposit a shell layer around the entire 𝑍𝑛𝑂 nanowires. For low density or small diameter, the shell deposition is easier but it reduces light absorption which degrades the efficiency of device. By changing the flow rate we can control the density of nanowires, and can get a favorable condition for the growth of coaxial nanowires.

From the above different experiments, we conclude that the growth parameters for well-aligned 𝑍𝑛𝑂 nanowires were used as 1.0 𝑔 of high-purity 𝑍𝑛 powder, 𝑁2 flow rate of 100 𝑠𝑐𝑐𝑚 , 𝑂2 flow rate of 8 𝑠𝑐𝑐𝑚 , growth temperature 580°𝐶 and the substrate position 8 𝑐𝑚 away from source material.

In summary, well aligned 𝑍𝑛𝑂 nanowire arrays have been synthesized by CVD. Different parameters, such as growth temperature, oxygen flow rate, and 𝑍𝑛 vapor pressure, have been modified to obtain the suitable conditions for aligned 𝑍𝑛𝑂 nanowire arrays.