We present a comprehensive summary of our observations of metal-rich particles in multicrystalline silicon (mc-Si) solar cell materials from multiple vendors, including directionally-solidifified ingot-grown, sheet, and ribbon, as well as multicrystalline flfloat zone materials contaminated during growth. In each material, the elemental nature, chemical states, and distributions of metal-rich particles are assessed by synchrotron-based analytical x-ray microprobe techniques. Certain universal physical principles appear to govern the behavior of metals in nearly all materials: (a) Two types of metal-rich particles can be observed (metal silicide nanoprecipitates and metal-rich inclusions up to tens of microns in size, frequently oxidized), (b) spatial distributions of individual elements strongly depend on their solubility and diffusivity, and (c) strong interactions exist between metals and certain types of structural defects. Differences in the distribution and elemental nature of metal contamination between different mc-Si materials can largely be explained by variations in crystal growth parameters, structural defect types, and contamination sources.

As newer multicrystalline silicon material evolved, the quantifified effect of different metal species on device performance was found to vary from earlier studies. It has become clear that in order to fully assess the effect of metals on solar cell performance, one must know not only the total concentrations of different metal species, but also about the spatial and size distributions of metal-related defects, their chemical natures, their interactions with different types of defects, and their behavior during the crystal growth process. In this study, we employ synchrotron-based analytical techniques to determine the aforementioned characteristics of metal contamination in a variety of mc-Si materials from multiple vendors. The conclusions drawn in this study are based on a large database of experimental data, which is much wider than a few typical metal distribution maps included in this article by way of example.

The mc-Si materials analyzed in this study are directionally-solidifified ingot-grown,sheet, and ribbon materials originating from a variety of vendors, and multicrystalline flfloat zone grown at the National Renewable Energy Laboratory. While comprehensive information about these crystal growth techniques, throughput, and crystal growth parameters can be found in the references hitherto and in a review by T. F. Ciszek,a brief summary is presented here to highlight the most relevant points for this study.

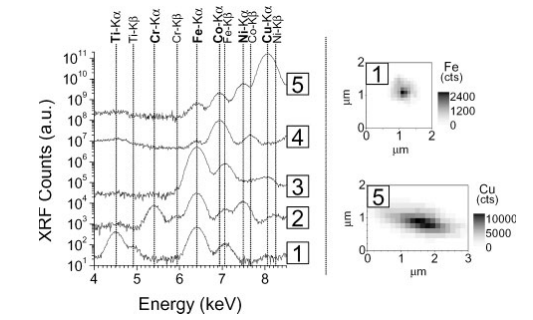

Fig1

Multicrystalline silicon ribbon materials vertically grown by nonsubstrate-assisted methods were analyzed on beamlines of medium sensitivity (ALS 10.3.1 and 10.3.2). While these beamlines could detect metal-rich particles in most other as-grown mc-Si materials, no metal-rich particles were detected in the ribbon materials analyzed in this study, despite total metal contents comparable2 to ingot-grown mc-Si. This suggests that metals in these ribbon materials are distributed more homogeneously and in smaller particles and point defects, below the detection limits of those beamlines. Higher-resolution beamlines, which have better sensitivities,15 are necessary for the detection of these smaller particles.

The metal-rich particles in all materials analyzed herein can be divided into two distinct classes: (a) the metal silicide (e.g., FeSi2, NiSi2, Cu3Si, etc.) nanoprecipitate, typically up to several tens of nanometers in diameter, most often associated with structural defects, and (b) the occasional larger particle, up to several microns in diameter, which is frequently oxidized, found within the grains, and/or composed of multiple slowly-diffusing metal species reminiscent of foreign material inclusions (e.g., coming from stainless steels, furnace material, etc.). These two distinct classes of metal-rich particle are shown in Figure 2, which portrays a representative mXRF map of an ingot-grown mc-Si sample from near the top of an ingot.