We have investigated thin fifilm of Indium Tin Oxide (ITO) deposited on glass substrates by thermal annealing and by H3PO4 chemical etching in order to improve their quality for use in polymer based light-emitting diodes. The morphology of the fifilm surface was signifificantly changed by both treatments as observed by scanning electron microscopy (SEM) and atomic force microscopy (AFM). The sheet resistivity of the annealed sample was found to be dependent on the annealing temperature, while it was practically not affected by the chemical treatment. On the chemically treated samples, analysis of the fifilm surface by X-ray photoelectron spectroscopy (XPS) revealed that a thin ionic phosphorus layer was formed on the ITO surface. The electrical and optical characteristics of light-emitting diodes with poly(2-methoxy,5- (20 -ethylhexyloxy)-1,4-phenylene vinylene) or MEH-PPV as an active layer, deposited on treated and untreated ITO substrates were determined and compared. Subsequent enhancement of performance of the diodes was obtained with treated ITO substrates, proving the effificiency of the performed treatments.

One of the factors that inflfluence the performance of organic light-emitting diodes (OLEDs) is the charge injection rate from the electrodes into the emitter. Because the injection mechanism occurs through the contact formed between the electrode and the organic material, the nature of the interface has a strong impact on the effificiency of the device. It has been found that the properties of indium tin oxide (ITO) used as an anode in OLEDs can affect the performance of the devices by its morphology as well as its electronic properties . It should be noted that the physical properties of ITO depend largely on the deposition techniques and its stability can be affected by the cleaning process. In search in improving the stability of the ITO fifilms, several investigations have been carried out to study modifification of the surface upon subsequent treatment including thermal treatment , plasma treatment, aquaregia treatment, and acid treatment.

ITO thin fifilms were prepared on glass substrates by electron beam deposition techniques. A commercial powder of ITO (supplied by Aldrich) was pressed into pellets, which were used as a crucible and evaporated by an 8.5 kW egun. The oxygen pressure in the chamber was set at 2 x10-4mbar during the evaporation and the temperature of the substrate was 200 8C. The thickness the ITO fifilm was about 500 nm as measured by a Tencor Alphastep profifiler. These samples are denoted as standard ITO samples.

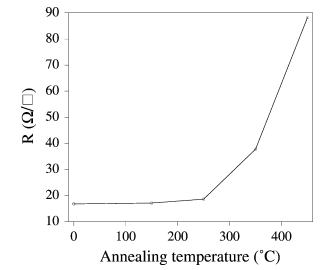

Fig3

Fig. 3 is a plot of the resistivity of the thermally treated ITO samples under ambient air as a function of the annealing temperature. We observe that at high temperatures, the resistivity increases but remains low. Notice that annealing the samples under vacuum does not alter the electrical conductivity.

As previously mentioned, the quality of ITO fifilms depends on the preparation methods. Several reports have mentioned substantial modififications of the optical properties of ITO after thermal treatments . These modififications were related to an enhancement of the crystallinity of the oxide induced by heat treatment. In these cases, a change in color was often observed in the ITO substrates, which became darker. The transmittance of the fifilms will decrease, in contrast with the results obtained in this study. In fact, we observe an improvement of the transmittance in the infrared region, while in the visible range it remains practically identical to that obtained in a standard ITO fifilm.

In this work, we have investigated the effects of thermal and acid treatments performed on electron beam deposited ITO thin fifilms in defifined conditions. The most signifificant changes observed in thermally treated samples are the increase of the grain size together with the resistivity when the annealing temperatures is higher than 250 ℃. The acid etching of the ITO surface in the used conditions also modifified the morphology of the fifilm. In addition, ionic species were found to be present on the surface. The electrical characteristics of diodes using MEH-PPV as an active layer were signifificantly improved by both treatments. The obtained improvement can be explained in terms of enhancement of the hole injection from the anode, favored by the formation of ionic species in chemically treated samples and, to a less extent, by the change in morphology of the surface in heat-treated samples, which increases the contact surface between the ITO substrate and the polymer fifilm.

上一篇: 硅片蚀刻MACE过程中化学镀金的优化