Particle removal from wafer surfaces can be accomplished by irradiation of cleaning fluid by sound waves in the MHz frequency range. Unfortunately, unless proper cleaning conditions are chosen, megasonic irradiation may also result in damage to fragile wafer features. Here, we demonstrate a strong effect of dissolved CO2 levels on the reduction of wafer damage during megasonic cleaning. Test structures with L/S patterns were irradiated with 0.93 MHz sound waves at varying power densities and dissolved CO2 levels, in a single wafer spin cleaning tool, MegPie® . Dissolution of increasing amounts of CO2 in air saturated DI water caused a significant decrease in the number of breakages to line structures and also decreased the lengths of the line breakages, at all power densities up to 2.94 W/cm2 . This ability of dissolved CO2 to protect against feature damage correlates well with its ability to suppress sonoluminescence in sound irradiated DI water.

Megasonic cleaning is routinely employed in the semiconductor industry for removal of contaminant particles and residues from wafer surface. With the progression of technology nodes to smaller sizes, megasonic cleaning is faced with the challenge of maintaining high cleaning efficiency without inducing damage to small features (~100 nm and less). Judicious choice of cleaning chemicals and control of dissolved gases has been proposed to minimize wafer damage.

Sonoluminescence (SL), the phenomenon of release of light when liquid is irradiated by sound waves of sufficient intensity, is a sensitive indicator of cavitation events (2). It is widely believed that acoustic cavitation is responsible for both wafer cleaning and damage. Intensity of SL correlates with intensity of cavitation, mostly transient cavitation that is believed to cause damage to wafer features. Therefore, control of transient cavitation has potential application in controlling damage.

The authors of this paper have previously reported the strong ability of dissolved CO2 to quench SL generation in DI water . It was shown that increasing amounts of dissolved CO2 progressively decreased SL and ~150 ppm dissolved CO2 was found to be sufficient to suppress SL generation in DI water under all conditions of power densityand duty cycle of acoustic energy at frequency 0.93 MHz It was also shown that CO isnot just incapable of supporting SL generation in DI water, but also a strong inhibitor ofSL generation in the presence of other gases that support SL generation.

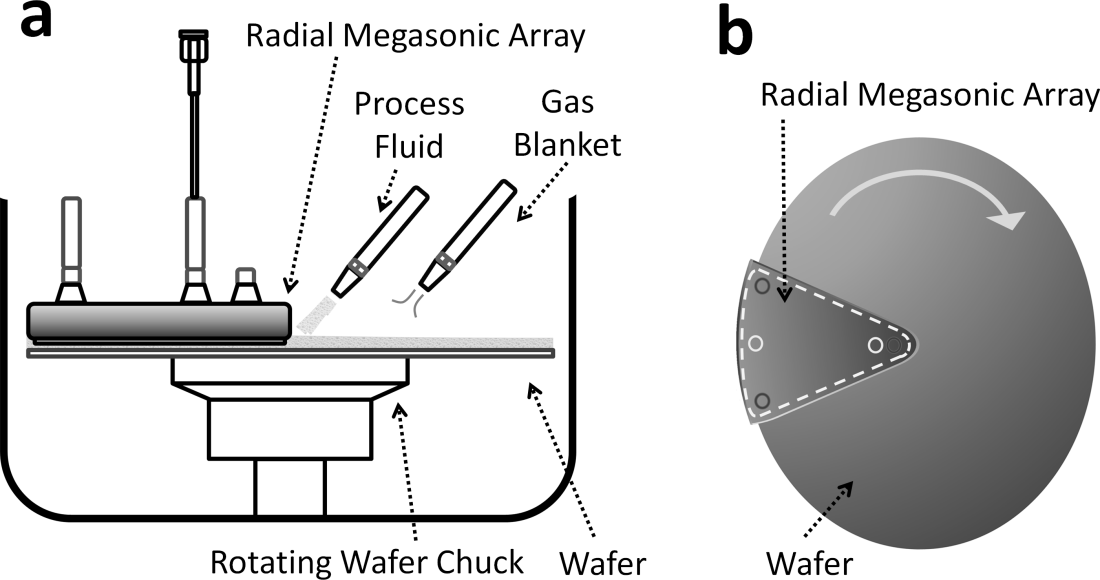

Fig1

Damages resulting from the exposure to megasonic energy were examined at low resolutions using an optical microscope and at high resolutions using a field emission scanning electron microscope (Hitachi S-4800, FESEM) (Fig. 3 and Fig. 4). For structures-I, width of the line features were small (~36 nm) and could not be resolved in an optical microscope. At a magnification of 200X, a large number of damage sites covering a representative area (0.3 mm x 0.4 mm) of the wafer, could be adequately resolved. These damage sites appeared as small dark spots (Fig. 3). Images for ten nonoverlapping and contiguous regions of damages, covering an area of 1.2 mm2 and occurring at a given power density, were collected and counted using the particle analysis tool in ImageJ (version 1.43u). For test structures-II, width of the lines were thick enough (~67 nm) to resolve in an optical microscope. A representative area of 0.08 mm2 constituting ten pairs of thin and thick lines was examined and the damage sites were counted manually. Total number of damages (line breakages) for both structures were scaled to 1 mm2 area of the wafer and plotted as a function of power density (Fig 5).

上一篇: 光刻胶溶解的原位表征