This dissertation has been submitted in partial fulfillment of the requirements for an advanced degree at the University of Arizona and is deposited in the University Library to be made available to borrowers under rules of the Library.

Brief quotations from this dissertation are allowable without special permission, provided that an accurate acknowledgement of the source is made. Requests for permission for extended quotation from or reproduction of this manuscript in whole or in part may be granted by the copyright holder.

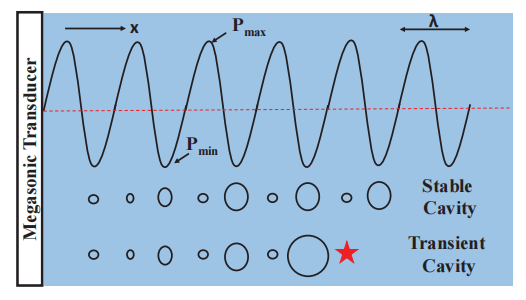

Over the years, megasonic energy has been widely used in the semiconductor industry for effective particle removal from surfaces after chemical mechanical planarization (CMP) processes. As a sound wave propagates through a liquid medium, it generates two effects, namely, acoustic streaming and acoustic cavitation. Acoustic streaming refers to time independent motion of liquid due to viscous attenuation, while cavitation arises from the bubble activity generated due to the difference in the pressure field of the propagating wave. Cavitation can be classified into two categories, (1) stable and (2) transient cavitation. When a bubble undergoes continuous oscillations over repeated cycles it is known to exhibit stable cavitation, while a sudden collapse is referred to as transient cavitation. Due to the rapid implosion of the transient cavity, drastic conditions of temperature (5,000-10,000 K) and pressure (hundreds of bars) are generated within and surrounding the bubble. If this phenomenon occurs close to the substrate, it causes damage to the sub-micron features. In this study, emphasis has been laid on understanding acoustic cavitation as it is critical to achieving high cleaning efficiency without any feature damage.

In the last part of the dissertation, we investigate the effect of solution parameters on cavitation characteristics using a bicarbonate based alkaline chemical cleaning formulation that has been previously demonstrated to be beneficial in achieving effective megasonic cleaning and low damage. The results of this study revealed that in the presence of ammonia (NH3) or carbonate/bicarbonate ions at concentrations greater than 75 mM or 200 mM respectively, the measured rate of generation of hydroxyl radicals at 1 MHz and 2 W/cm2 was significantly reduced. The lower rate of OHx was attributed to scavenging of radicals in these solutions and additionally due to reduced transient cavitation in ammonia solutions. Hydroxyl radical measurements at higher power density of 8 W/cm2 showed that carbonate ions were better scavengers of hydroxyl radicals than bicarbonate ions. The study on the effect of bulk solution temperature illustrated that the rate of generation of OHx increased with increase in temperature from 10 to 30 qC suggesting enhanced transient cavitation at higher temperatures (in the investigated range). The use of optimum concentration of ammonia or carbonates ions in cleaning formulation and bulk solution temperature would likely provide desired cleaning with minimum damage.

As the technology node keeps getting smaller, there arises a need to clean the submicron components of a chip with minimal damage. The presence of small particles requires increased hydrodynamic flows to be able to lift the particles off the wafer surface. With the current cleaning methodologies not capable of efficiently remove contaminants, the use of acoustics (megasonics) has been adopted. The significance of this process is that the boundary layer is several orders of magnitude lower than conventional technologies and provides an advantage for particle removal. A considerable amount of work has been performed in this field, and acoustic frequency and power density of 0.8-1 MHz and up to 7.75 W/cm2 have shown efficient particle removal. As with every technology, there is a drawback in using megasonics in that it causes feature damage. The work presented in this dissertation focuses on developing technologies and optimizing process parameters to ensure damage-free cleaning.

Fig3

Removal of particles from semiconductor surfaces could occur as a result of streaming forces generated either by stable or transient cavitation. For achieving damagefree particle removal, it is critical to eliminate transient cavitation because of its extreme conditions. In the sections to follow, more details are given with respect to the available literature regarding the mechanisms involving particle removal and some preliminary calculations to understand the process at megasonic frequencies.

Figure 3 shows the different stages involved in the evolution of bubbles in the presence of a sonic field. The evolution process can be broken down into three phases, namely, inception, activity and effects thereof. Inception refers to the process of initiating the formation of cavities and as shown in Figure 3 depends on the solution chemistry (viscosity, dissolved gases, impurities) and operating field parameters (frequency, power density, duty cycle). There exists a threshold value of pressure beyond which discernible cavitation activity is exhibited. For instance, in pure water containing no nuclei (like dissolved gas), about 1300 atm of pressure would be required to overcome the surface tension forces of water to initiate a bubble with a radius of 1 nm as shown from the equation below.

上一篇: 锗(Ge)晶圆清洗液开发