Methods and apparatus for detecting the presence or absenceof unwanted metal deposits on a substrate holder of anelectroplating apparatus are described herein. In variousembodiments, a plating sensor is used to detect unwantedmetal deposits. The plating sensor may be mounted rela-tively far away from the area that it measures (eg., thesensor target area). For instance, the plating sensor may beon one side of the electroplating apparatus (in some casesmounted on a drip shield), and the sensor target area may beon the opposite side of the electroplating apparatus. In thisway, the plating sensor can measure across the electroplatingapparatus. This placement provides a relatively deep depthof focus for the plating sensor, and provides some physicalseparation between the plating sensor and the electroplatingchemmistry. Both of these factors lead to more reliable detec-tion results.

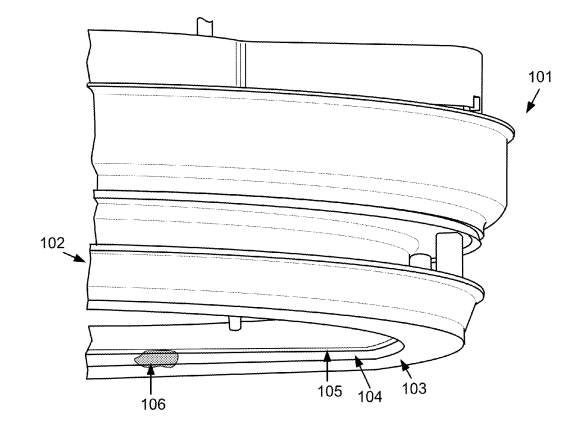

In one aspect of the embodiments herein, an electroplat-ing apparatus is provided, the apparatus including: an elec-trolyte vessel configured to hold electrolyte during electro-plating; a substrate holder configured to support a substrateduring electroplating, where the substrate holder is annularlyshaped and supports the substrate at its periphery, thesubstrate holder including a sensor target area; and a platingsensor including a light source aimed at the sensor targetarea, where the plating sensor distinguishes between (i)areas on the sensor tanget area where unwanted metaldeposits are present and (ii) areas on the sensor target areawhere unwanted metal deposits are absent.

The electroplating apparatus may further include a dripshield. The plating sensor may be positioned on the dripshield. The drip shield may include a wall and a centralopening through which the substrate holder fits, The wallmay be a peripheral wall that defines the central opening. Ina particular embodiment, the apparatus includes a dripshield, where the plating sensor is positioned on the dripshield. In these or other cases, the drip shield may include awall and a central opening through which the substrateholder fits. The plating sensor may be various types ofsensors. For instance, the plating sensor may be a color-based sensor, an intensity-based sensor, or a camera.

The electroplating apparatus may further include a dryerthat dries the sensor target area. In some such cases, theelectroplating apparatus may further include a controllerhaving executable instructions to dry the sensor target areapriar to detecting the presence or absence ofunwanted metaldeposits using the plating sensor. In these or other cases, thesubstrate holder may be rotatable with respect to the platingsensor. In a number of embodiments, the electroplatingapparatus includes an inlet configured to deliver fluid to thesensor target arca. In some such cases, the electroplatingapparatus may further include a controller having executableinstructions to wet the sensor target area with fluid after theplating sensor is used to detect the presence or absence ofunwanted metal deposits in the sensor target area and beforethe electroplating apparatus is used to electroplate on a newsubstrate.

Fig1

One alternative cleaning method includes rotating a clean-ing disc that has cleaning fluid therein, where the rotationresults in the cleaning fluid emanating from peripheral poresin the disc. The cleaning solution then contacts the substrateholder to remove the unwanted deposits. In some embodi-ments, the disc may have a substantially circular uppersurface a substantially circular lower surface, a substantiallycircular edge joining the upper and lower surfaces, and aplurality of pores opening at the edge, The disc may alsohave an interior region extending into the interjor ofthe disc.In some embodiments, the pores are dimensioned such thatthe cleaning agent is retained in the interior of the pores byan adhesive force between the cleaning agent and theinterior surface of the pores. One method of using such acleaning disc may involve loading a cleaning agent into aplurality of pores of the cleaning disc, positioning thecleaning disc within a semiconductor processing apparatus,and rotating the disc or otherwise manipulating the disc torelease cleaning agent from the plurality of pores such thatelements of the apparatus are contacted by the releasedcleaning agent. This cleaning technique and apparatus there-fore are further described in US. Pat. No.9221,081, whichwas incorporated by reference above.

上一篇: 原子层沉积系统